5. Mapping the Building Materials

Determining whether building materials contain PCBs is only possible by collecting samples and sending them for chemical analysis. This section lists building materials admixed with PCBs and details where the materials are located, where samples should be collected, and how many samples to collect both in introductory and follow-up mapping. Furthermore, potential secondary and tertiary sources are described. The actual sampling is described in Section 8, Determining PCB Content in Building Materials.

Guidance is available electronically via the PCB-guide (www.pcb-guiden.dk) and from the City of Copenhagen (City of Copenhagen, 2014 and www.kk.dk). The Danish EPA issues guidelines on managing insulating glazing units containing PCBs (Danish EPA, 2014) and guidance on sampling is available on the Norwegian website www.ruteretur.no. The Danish EPA has also issued guidelines on handling PCB-containing capacitors in fluorescent light ballasts (Danish EPA, 2015). Guidance on how to collect samples of materials can be found on the Swedish website www.sanerapcb.nu. Finally, the report Forekomst af PCB i en- og tofamiliehuse (Presence of PCBs in Single- and Two-Family Dwellings) (Jensen et al., 2009) is a good source of information on PCBs in construction products.

5.1 Scope of Mapping

Outlined here is a description of the scope of mapping broken down according to whether it was prompted by a survey of health-related issues or by requirements in the Statutory Order on Waste due to renovation or demolition.

5.1.1 Health Issues

The mapping of materials supplements the mapping of indoor air. It is typically conducted stepwise with introductory mapping identifying the primary sources and follow-up mapping also including the secondary and tertiary sources.

Complete mapping of PCB content in materials provides a sound basis for choice of remediation methods. Often, remediation will be a combination of various abatement interventions, but the overall result will never be better than the least efficient intervention.

Thus, PCB concentrations in indoor air can still be excessive following careful removal (e.g., of windows with caulked expansion joints and adjacent concrete (primary and secondary sources)), meticulous cleaning, and establishing increased balanced ventilation. This is caused by PCBs from tertiary contaminated walls, floors, and ceilings or from residual primary or secondary sources now starting to off-gas into the indoor air.

Introductory Mapping

An introductory survey will focus attention on the most obvious primary sources (i.e., caulk, insulating glazing units, floor paint, and capacitors). Moreover, in multi-storey residential buildings, business and industrial buildings, special attention will be given to certain paint types, flooring, and wet-room materials (see Table 17, Section 5.2, Construction Products Potentially Containing PCBs).

Follow-up Mapping

If the introductory survey shows that PCB-containing building materials exist in the building, it will be necessary to conduct one or more mappings of relevant parts of the building. This includes both an identification of primary sources, namely the building materials originally admixed with PCBs during production, and the secondary and tertiary sources. This is because all potential occurrences of PCBs must be identified to achieve successful remediation and to ensure an acceptable working environment and waste management.

5.1.2 Renovation or Demolition?

The mapping is typically conducted stepwise and broken down into introductory mapping and one or more follow-up mappings (which also include secondary and tertiary sources). In the case of renovation or demolition, the PCB-containing materials to be removed from the building should be identified and decisions on separation and classification of the building materials made in accordance with the Statutory Order on Waste (see Section 3, Surveys Prior to Renovation or Demolition).

Introductory Mapping

The introductory mapping concerns PCB-containing building materials based on Table 17, Section 5.2, Construction Products Potentially Containing PCBs. During renovation, the building materials to be removed from the building are investigated whereas all relevant building materials in the entire building are investigated during demolition. When renovating (e.g., a wet room in a housing complex), building materials potentially containing PCBs in wet rooms would be investigated and not just the most obvious primary sources. If PCB-containing materials are identified, the next step will be to examine potential migration to adjacent materials and surface areas.

PCB-containing materials may be concealed in the construction. To achieve the best possible planning of the building process, it is important to know as much as possible about potential occurrences of PCBs (see also SBi Guidelines 242, Renovering af bygninger med PCB, 1 Renoveringsproces (Renovating Buildings Containing PCBs, 1 Renovation Process) (Andersen, 2013b). In renovation projects where the planned work involves opening the construction, as far as possible this should be done in connection with the mapping process and the relevance of sampling should be assessed.

Furthermore, sampling of potential tertiary sources (e.g., wall paint and flooring) can be performed. Based on existing knowledge, the number of samples is a matter of judgment. The aim of sampling potential tertiary sources is to reduce the risk of overlooking PCBs (e.g., those concealed in constructions). Even a faint increase in PCB concentrations in indoor air would presumably be reflected in paint and certain types of flooring like linoleum. However, it may be difficult determine whether paint and flooring are primary or tertiary sources.

If sampling indicates significant amounts of PCBs in the building materials, air samples should be collected to clarify whether adverse health conditions exist in the building.

Follow-up Mapping

If analyses indicate the existence of PCBs in the building materials, the next step will be one or more follow-up mappings. This means an identification of primary sources as well as secondary and tertiary sources. Their PCB content is significant for the clean-up method used, plus considerations relative to the working environment and waste separation.

Although the building is renovated for other purposes than remediating PCB problems, it may often be necessary to map the PCB content of building materials over and above the requirements set out in the Statutory order on waste. It may be necessary to conduct further mapping to examine how the renovation will affect the building and the health conditions in the building. Exterior caulked joints containing PCBs must be considered if exterior re-insulation is planned, as these will be positioned inside the new climate envelope and the new insulation. Thus, they may emit PCBs to the indoor air. Furthermore, a renovation which changes the air exchange rate in the building require close examination if PCBs are present in indoor air. It may be necessary, therefore, to investigate indoor air PCB concentrations both before and after the renovation (see SBi Guidelines 242, Renovering af bygninger med PCB, 1 Renoveringsproces (Renovating Buildings Containing PCBs, 1 Renovation Process) (Andersen, 2013b). It will also be necessary to ensure that the working environment is safe.

5.2 Construction Products Potentially Containing PCBs

Interior and exterior caulk, flooring compound, floor paint, and exterior paint in blocks of flats, industrial and institutional buildings pose the greatest risk of PCB contamination, as do detached and terraced houses built by major building firms during the period 1956-1976 (Jensen et al., 2009). Moreover, it is relevant to investigate insulating glazing units in all buildings from the period when PCBs were used in edge sealants and in mounting materials for the units. It is also relevant to investigate whether there are electrical appliances containing capacitors, such as fluorescent light ballasts, ventilators, motors, and pumps.

Table 17 lists the construction products used in various dwelling types between 1950 and 1977. The risk that PCBs are present in these construction products has been graded based on known data from Denmark (Jensen et al., 2009). The numbers of the individual construction products used are estimated and listed in Section 1.4.2, Usage and Residual Amounts of PCBs.

If building materials containing PCBs are detected (i.e., primary PCB sources) there are very likely materials in the building, which are secondary and/or tertiary contaminated PCB sources, and these also require investigating.

Construction Product | Typically Found in/on | Single-Family Dwellings, Bungalows | Row and Terraced Houses | Multi-Family Dwellings | Farm Houses | Blocks of Flats | Industrial and Office Buildings |

|---|---|---|---|---|---|---|---|

Caulk | Windows and doors, partition walls, precast slab joints, floor joints, balconies, pipe penetrations | ||||||

Sealant tape | Windows and doors, partition walls, precast slab joints, by beams and glazing bead profiles, etc. | ||||||

Insulating glazing units | Windows and doors, glazing unit sealants | ||||||

Thermal putty | Windows, doors, joints by gullies | ||||||

Fire-retardant paint | Steel structures, fire barriers | ||||||

Anti-corrosive paint | Metal components of iron | ||||||

Adhesives | Floors, panels, ceilings, laminated structures and elements, worktops | ||||||

Capacitors | Fluorescent light ballasts, industrial motors | ||||||

Cables, wiring, switches, plates | Electrical installations | ||||||

Fillers | Floors and walls | ||||||

Rubber surfacing | Wet rooms | ||||||

Anti-skid surfacing | Access balconies | ||||||

Thick-film paint | Exterior concrete | ||||||

Lacquer | Wooden floors | ||||||

Linoleum, vinyl, carpets | Flooring, worktops | ||||||

Self-levelling flooring compounds | Floors | ||||||

Wax, polish, and similar | Floors | ||||||

Floor paint | Wet rooms, utility rooms, concrete stairs, workshop, and industrial floors | ||||||

Plaster, mortar, concrete | Walls, ceilings, floors | ||||||

Laminated plastic | Cupboards, worktops, wall panels | ||||||

Building boards | Floors, walls, ceilings | ||||||

Tile adhesives | Floors, walls | ||||||

Waterproofing materials, waterproofing primer | Wet rooms, utility rooms, kitchens |

◆ = Widespread occurrence based on known data from Denmark.

◆ = Possible occurrence based on known data (only a few cases found in Denmark).

◆ = No/inadequate data.

5.2.1 PCBs in Caulk

PCB-containing caulked joints have been identified both inside and outside (see Section 1.4.4, Caulking Compound) and both interior and exterior caulk should therefore be investigated. It is impossible to see or otherwise physically determine whether building materials contain PCBs and a chemical analysis is therefore required.

Most caulked joints tend to grow hard over time because they desiccate. Over time, many caulked joints may acquire a crumbling, crocodile-skin-like surface and be prone to chalking (producing white dust on the surface which can be wiped off) (Fugebranchens samarbejds- og oplysningsråd, 1994). Polysulphide caulk was chiefly used outside (see Section 1.4.4, Caulking Compound) and freshly sheared edges have a characteristic smell of sulphur.

Evidence shows that PCB content in caulk may differ widely relative to type, position, and weather impact. Even in the same joint around a window, there may be marked differences in concentrations (Sundahl et al., 1999). This presents a challenge when collecting samples, since it is not easy to estimate how representative a sample might be. The number of required caulk samples depend on:

- Size of the building

- Variations in types of caulked joints and their appearance

- Sampling aims

Figure 13 shows an exterior caulked joint between facade units, continuing between wall and window.

Figure 13. Exterior joint between facade units, continuing between wall and window.

PCB concentrations in caulk may vary significantly. There are known examples of polysulphide caulk with an original PCB content of 5–30 % typically (Gunnarsen et al., 2009). There are also caulks with a low PCB content possibly derived from a contamination during mixing or from the caulk gun. The original caulk may have been removed and the new caulk could have been polluted by any residual caulk or by PCBs that migrated from adjacent materials (secondary sources contaminated by the old caulk and in turn contaminating the new caulk).

Where are the Caulked Joints Located Which Might Contain PCBs?

Caulk is used everywhere in buildings where two components or materials abut and where no visible cracks are desired either for technical or aesthetic reasons. Table 18 lists several locations where caulking compound may have been used.

Location | Particular Areas | Caulk type and function |

Brick facades | Long facades near corners and downpipes. A joint will typically be placed for every 15–30 m. | Vertical expansion joints to prevent cracks in the brickwork. |

Between building | Between large units of | Expansion joints to prevent elements from expanding or |

elements and components | different materials | contracting at different rates due to different thermal expansion coefficients. |

Between concrete stairs and building components | Caulked joints to prevent sound transmission via concrete stairs. The stairs are mounted with pin bolts on a neoprene underlay and the holes between house and stairs may have been filled using elastic caulk. | |

Between existing house and extension | Caulked joints to offset differential settings. Two buildings erected at different times, each with its own foundations, will normally set differently. | |

Between facade units | Especially two-stage joints to ensure continuation and tightness between units (see Annex C, Joints). For reasons of damp-proofing, the exterior joint must be vapour-permeable whereas the interior joint must be vapour-impermeable. This principle was not always observed, which is why PCB-containing caulk is sometimes found outside. Furthermore, sealant tape (rubber profiles or pre-compressed) may contain PCB. | |

Between house and access balconies/balconies | Joints ensuring continuation between façade and horizontal unit if the house is precast with access balconies and balconies. If balconies and access balconies rest on timber beams, there will be caulked joints around the beams whereas there will be cavities (air) between unit and façade. | |

Columns | Joints ensuring tightness between columns and building components. | |

Cracks | Joints filling and hiding cracks between units. The cracks need not have any impact on the durability of the house. If elastic caulk is used, the caulk can absorb movements, avoiding new cracks. | |

Around doors and windows, and glazed facade units | One- or two-stage joints ensuring continuation and tightness between units (see Annex C, Joints). | |

Behind battens or facade cladding | Concealed joints. | |

Inside, around doors | Joints preventing cracks resulting from seasonal air moisture content. Walls (e.g., of brick, aerated concrete, concrete, or gypsum) are less sensitive to moisture than wooden doors, which change in size over the year. | |

Floor joints | Large concrete surface areas | Expansion joints in concrete floors. Concrete shrinks when it dries. In large concrete floors, expansion joints are laid which will both absorb temperature-related dimensional changes and prevent shrinkage cracks. |

Expansion and contraction joints in construction joints. | ||

Between floors and walls | Expansion joints. Depending on how a floor is cast, there may be joints between the floor and wall. | |

Joints around pipe penetrations | Joints to absorb movements and ensure water and airtightness. The pipe will undergo temperature changes more quickly than the surrounding walls or decks. Often, joints will be added for acoustic or fire-related reasons. |

Along bottom bead profiles and glazing bead profiles in windows | Top sealant ensuring tightness between the glazing and the casing. The top sealant is laid on top of the sealant tape between the pane and the bottom bead profile and window bead profiles. | |

Between exterior walls and interior partition walls | Joints to limit sound transmission. There are also examples of sound insulation between walls and partition walls where caulk containing PCBs has been used. | |

In wet rooms and | In corners, expansion areas | Joints to ensure watertightness. Watertightness can be achieved |

swimming pools | with wet room tanking membrane | in several ways: It can be a waterproofing primer (thick paint or system of multiple layers of paint) or a foil membrane (roll material). Irrespective of whether a waterproofing primer or foil membrane has been used, there could be cracks in the corners or expansion areas caulked with elastic caulk. |

In wet rooms with a tiled surface, there might be elastic caulk in the corner between two walls and between floor and wall. | ||

In basins, for example for water, tubs and containers | Major concrete structures | In corners or as expansion joints in major concrete structures, watertight joints may be necessary. It would be necessary, therefore, to apply elastic caulk. |

Construction joints | In construction joints for watertight assemblies, joints strips (rubber profiles) may have been inserted into the concrete. |

Table 18. Possible locations of elastic and plastic caulk containing PCBs.

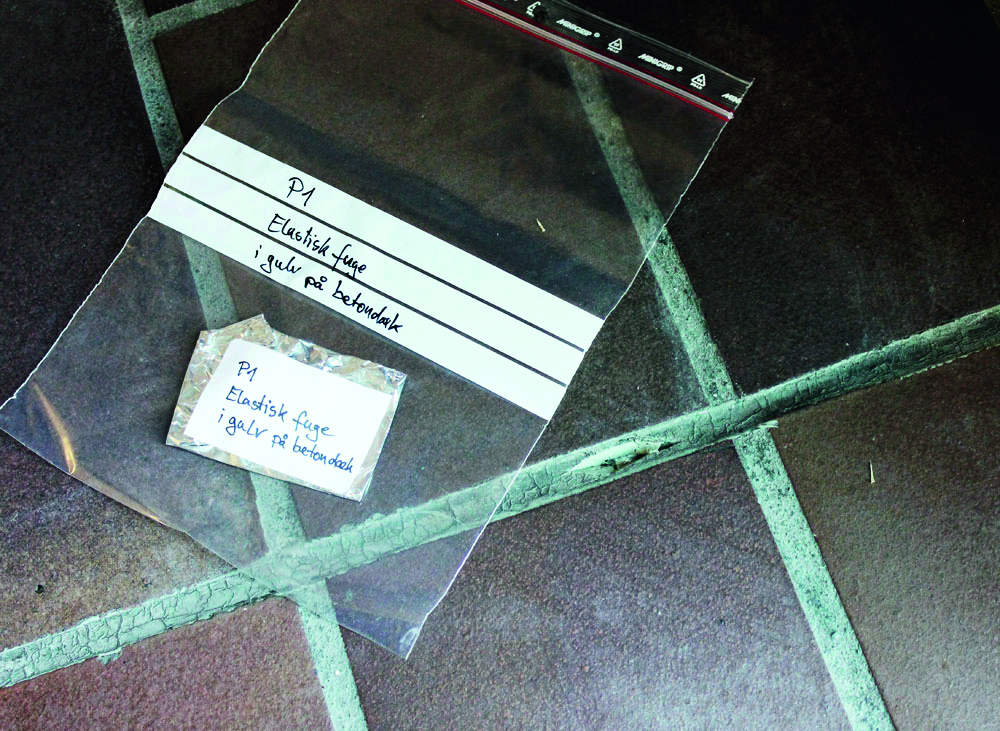

Figure 14 shows an expansion joint in a floor between concrete decks.

Figure 14. Expansion joint between concrete decks. Photo: Danish Technological Institute

Strategy for Collecting Caulk Samples

When mapping, one or more samples should be collected from all types of caulk classed as identical (i.e., presumed to be of the same type and exposed to the same conditions). Whether the conditions are identical depends on the orientation of the façade. South- and west-facing facades are exposed to tougher weather conditions of sun and driving rain than are east- and north-facing facades.

Similarly, indoor conditions may vary (e.g., due to solar heating or heating from radiators). A strategy for collecting caulk samples, therefore, should be determined in each separate case based on a concrete assessment of these issues.

Composite Samples

Aliquots can be pooled to make a composite sample (e.g., five aliquots of caulk composited to form one sample). This may be necessary to achieve a mean target for caulk classed in the same group (cf. below). Further information can be found in Section 5.2.1, PCBs in Caulk, and Figure 21 in Section 8.2.3, Step-by-Step Procedure: Collecting Caulk Samples. It could also be economically necessary. The composite sample can verify whether PCBs are present in one or more of the aliquots and whether a more detailed sampling is called for.

The aliquots are sent as one composite sample to the testing laboratory with information on test type, etc. The laboratory pools the samples, typically by taking roughly equal-sized pieces from each type of caulk and mixing them. Thus, in the further processing and chemical analysis, only one sample is analysed for PCB content.

Classification of Caulk

During the original building phase or renovation, different materials may have been used in the buildings. Each building should therefore be considered an independent unit although it is part of a large-scale development where the buildings look alike and appear to be built of the same type of materials.

For large-scale developments, it will be necessary to classify the caulked joints. The locations of the caulked joints should be identified internally and externally based on drawings, available information, and observation.

- The caulked joints should be divided according to type: facade, interior joints around doors, etc.

- A subdivision of each joint should be made according to impact (e.g., from the weather, solar radiation) (internally and externally), and the specific usage of the room (e.g., wet room).

- A second subdivision should be made according to appearance.

Figure 15 shows an interior light grey and cracked wall joint in a classroom.

The various types of caulked facade joints are described in Annex C, Caulked Joints. When inspecting the facade, please note that two-stage joints are common, meaning that samples should be collected from both the inside and outside. Moreover, caulked joints may be concealed behind the facade cladding and behind openings.

Adverse weather effects are most common in south- and west-facing facades.

An assessment should determine whether they can be classed together or should be subdivided. This also applies to east- and north-facing facades. In multi-storey residential buildings, an assessment must be made as to whether caulked joints on different storeys should be characterised as identical.

Figure 16 shows how joints are divided on a south-facing facade in a multi-storey residential building with external balconies. Here, the weather impact on the facade is regarded as relatively even and the storeys look alike. The caulked joints are characterised according to colour, consistency, and condition.

Figure 16. Example of caulk on a south-facing facade categorised according to type, colour, consistency, and condition.

After inspecting and dividing the facade caulk into caulk groups, the groups are described in a diagram (see the example in Table 19).

Table 19. Example classification of exterior caulk on a south-facing facade. The caulk is divided according to location, type, consistency, and condition.

Location | Caulk around doors and windows | Caulk between slabs and walls | Caulk between building and stairs, balcony, access balcony, etc. |

South-facing | grey, hard, cracked grey, hard, intact | grey, hard, intact | grey, soft, intact |

When classifying the caulk according to type and possibly subdividing it according to appearance and impact sustained, the sampling can be planned.

Interior Caulk

One should check if there is caulk around doors and windows and the rooms in the building should be examined considering Table 18. Identical caulked joints should be identified according to the same principle as for facade caulk and samples should be collected from each identified subgroup.

Preliminary Investigation

Caulked joints should be inspected as part of the preliminary investigation, as they may contain PCBs. In major construction projects, a preliminary investigation can be conducted after having identified groups and subgroups of identical caulked joints by collecting samples of caulk form each group.

The samples could be collected as composite samples consisting of one sample from each subgroup (see section 8.2.3, Step-by-Step Procedure: Collecting Caulk Samples). This will provide information on PCB presence, but actual quantification requires knowledge of each subgroup.

Follow-up or Full Mapping

For detailed or full PCB mapping, at least two samples must be collected from each subgroup. When collecting the samples, an assessment is made as to whether the consistency of the samples is uniform (i.e., whether the samples are indeed from one subgroup or whether further subdivisions are necessary).

The concentration of PCBs in the caulk may vary a lot even around the same window and if a higher degree of assurance is required, more aliquots can be collected from each subgroup to make up a composite sample (see above). Aliquots of the same-size should be collected for the composite sample. The testing laboratory should be notified that it is a composite sample.

Major Construction Projects

For a building with many caulked joints and/or many windows, composite samples can be collected where the caulked joints are classed within the same group or subgroup across an extended area. As mentioned above, every building should be considered an independent unit.

Concentration and Secondary Sources

PCB-containing caulk may result in excessive PCB levels in indoor air (see section 1.6.1, Factors Affecting PCB Concentrations). PCB concentrations in caulk are important for the purpose of waste classification. PCB concentrations in caulk are also relevant for assessing sampling locations when secondary contaminations in adjacent materials must be localised. However, there is not necessarily a correlation between PCB concentrations in the caulk and the degree of migration. The migration of PCBs to adjacent materials is detailed in Section 1.5.2, Secondary Contamination of Building Materials.

5.2.2 PCBs in Insulating Glazing Units

The edge sealant or packing between the glazing and spacer profile is not immediately visible because this area of the glazing unit is typically covered by bead profiles (see Figure 25, Section 8.3.1, PCBs in Insulating Glazing Units). A Danish glazing unit produced in or before 1977 may contain PCBs (see Section 1.4.5, Insulating Glazing Units, and guidelines issued by the Danish EPA on handling PCB-containing glazing units) (Danish EPA, 2014). Foreign insulating glazing units may contain PCBs if produced in or before 1980.

Insulating glazing units may be held in the casing by putty or plastic sealant tape, which may contain PCBs (see Figure 25).

Labelling

In newer glazing units, product information is stamped on the unit’s spacer profile (see Figure 17). It may be difficult to see the label and the use of a flashlight may help to locate it. Certain older glazing units provide this information, but not all. If the glazing unit is not labelled, it very likely predates 1977 when the PCB ban came into force, and it could contain PCBs. The spacer profile might be labelled as follows:

- Production date (e.g., ”10/72”, indicating the production date of October 1972).

- ”DS 1094”, indicating that the glazing unit was produced in accordance with the standard DS 1094, published in its first edition in 1983. Thus, it can almost certainly be ruled out that insulating glazing units labelled ”DS 1094” contain PCBs (Vestforbrænding et al., 2008). However, this does not rule out the possibility of PCB contamination if the glazing unit replaced one that did contain PCBs.

The labelling ”GS” followed by a number was introduced along with the DS 1094 labelling. This means that the glazing manufacturer is a member of Glasindustrien (the glass industry), and the number indicates the manufacturer’s membership number.

Figure 17. Insulating glazing unit with aluminium spacer profile between panes.

Replacement Frequency

Insulating glazing units in a building are unlikely to be of the same age as some of them are likely to have been replaced. Insulating glazing units in doors and hinged windows break more frequently or puncture before those in fixed casings. In rooms with high insulation requirements such as dwellings or office buildings, the glazing units will often have been replaced while units in storerooms or other rooms with less stringent requirements are only replaced if they break.

Mapping

During the mapping process, all glazing units in the building should be inspected with a note indicating their label, if relevant. If the insulating glazing unit predates 1977 or is of foreign origin predating 1980, sampling will be necessary. Moreover, the mounting of the unit should be examined carefully as putty and plastic sealant tape may complicate the dismounting.

An insulating glazing unit measuring approx. 1 m2 may typically contain 50 g PCBs in the edge sealant (Vestforbrænding et al., 2008; www.ruteretur.no) (see Section 1.4.5, Insulating Glazing Units). Insulating glazing units containing PCBs in the edge sealant should therefore be disposed of as hazardous waste. If only the glazing unit is removed, please note that both rebate and window casing can potentially be contaminated by PCBs derived from the edge sealant or the mounting materials, which is important when disposing of the window casings. Furthermore, the edge sealant and/or mounting materials will be exposed, and careful handling is required to avoid exposure of humans to PCBs, and to prevent PCBs from migrating to the environment (see the guidelines issued by the Danish EPA on handling PCB-containing insulating glazing units) (Danish EPA, 2014).

Window casings may be contaminated by PCBs because PCB-containing glazing units or mounting materials may have previously been used in the casings (see Section 5.2.6, Secondary Contaminated Building Materials).

When replacing glazing units potentially dating from the period 1950–1977, the requirement for screening stipulated in the Statutory Order on Waste will apply (see Section 3, Surveys Prior to Renovation or Demolition).

5.2.3 PCBs in Paint

Certain types of paint contained PCBs (i.e., they may have been primary sources). If the paint does not contain PCBs, it may sorb PCBs from the air and thus be a tertiary source (see Section 1.5, Primary, Secondary, and Tertiary Sources). Furthermore, paint may sorb PCBs from primary sources if they are in direct contact (e.g., wall paint along a caulked joint containing PCBs or paint applied to PCB-containing filler). In this case, the paint is a secondary source.

In multi-storey residential buildings, paint has been found with PCB concentrations above 50 mg/kg in interior stairwells, washrooms, storage rooms, basement bike storage rooms, and boiler rooms. The paint was applied to the floor, walls, soil stacks, and metal railings (Grontmij & COWI, 2013). In single- and two-family dwellings, PCB-containing paint was discovered on interior water pipes in toilets and on floors in larders, washrooms, office and storage spaces, and exterior stairs (Grontmij & COWI, 2013).

Detailed below are the places where one would typically find different types of paint possibly containing PCBs (i.e., primary sources).

Fire-Retardant Paint

Fire-retardant paint is used for many visible supporting structures of steel, including stairs, timbers, and columns. Steel structures must be protected against fire, as they would otherwise heat quickly and lose their strength and rigidity.

Anti-Corrosive Paint

PCBs have been confirmed in anti-corrosive paint in multi-storey residential buildings and industrial and office buildings (see Table 17). Anti-corrosive paint is used on steel internally and externally to prevent rust in conditions when the relative humidity exceeds about 65 %.

Thick-Film Paint

Thick-film paint is typically used in a paint system where the thick-film paint possesses specific properties (e.g., the capability to stop carbonation in concrete). Such a system will normally also comprise a thin-film paint, providing the desired appearance.

Floor Paint

PCB-containing floor paint has been discovered in industrial and office buildings and in single- and two-family dwellings, waterworks, and other technical buildings (see Table 17).

There may be floor paint in wet rooms, utility rooms, on concrete stairs, and on the floors in workshops and industrial buildings.

Mapping

When collecting paint samples, the following should be investigated:

- Are there locations where paint containing PCBs may have been used to boost abrasion resilience, retard fire, or protect against corrosion?

- Is there, or was there, PCB-containing caulk in contact with painted surfaces?

- Does the indoor air contain PCBs to an extent that may cause tertiary PCB contamination of painted surfaces?

A follow-up mapping comprises an inspection of all painted surfaces in the building and collection of samples for each paint type and colour according to the three criteria above. If the indoor air is contaminated by PCBs, samples of the tertiary contaminated surface areas will be necessary before separating out waste (see 5.2.7, Tertiary Contaminated Materials). When collecting samples of paint from interior walls, it is important to ascertain whether the wall could be a recent addition and not necessarily subject to tertiary contamination to the same extent as other walls in the room. This also applies to conversions or extensions.

5.2.4 PCBs in Capacitors

Certain types of capacitors contain oil and during the period 1950–1986, this oil may have contained PCBs in so-called closed applications (see Section 1.8, Rules). This also applies to large oil-cooled high-voltage transformers (Danish EPA, 2000). There are requirements for the disposal of large transformers (more than 2 kVAr) and capacitors (more than 1 kg) by 1 January 2000 while smaller capacitors and transformers were permitted to be used for the remainder of their lifespans (Danish EPA, 1998) (see Section 1.8, Rules). In 2000, it was estimated that a limited amount of PCBs were still in use in large capacitors for power factor correction (e.g., in industrial enterprises, hospitals, universities, incineration plants, water treatment plants, and large farms) (see the Danish EPA, 2000).

In the case of large capacitors and transformers, there is a chart on the Danish EPA’s website listing brand names containing PCBs (Fortegnelse fra 1988 over transformatorer og kondensatorer indeholdende PCB (1988 List of Transformers and Capacitors Containing PCBs)) (www.mst.dk).

Capacitors for Mains Voltage

Capacitors for mains voltage potentially containing PCBs is used in ballasts for power factor correction in fluorescent light ballasts and certain types of sodium and mercury lamps as well as starter motor capacitors in white goods and capacitors in microwave ovens (Danish EPA, 1983 and 2000). Sodium and mercury lamps are used for outdoor lighting, industrial and sports facilities, among other applications (Danish EPA, 2015). Most of the remaining PCB-containing capacitors are estimated to exist in fluorescent light ballasts and other light fittings (Danish EPA, 2015).

If a building was erected prior to 1987 it may contain electrical appliances estimated to date from the period 1950–1986 and these may contain capacitors with PCBs. The Danish EPA (2015) has issued guidelines on handling PCB-containing capacitors in light fittings which detail how to determine whether a light fitting may contain a capacitor with PCBs. This also applies to capacitors for electrical signs and sodium and mercury lamps. Working with electricity can be dangerous and applicable rules and safety concerns should be considered and complied with.

Fluorescent light ballasts are fitted with PCB-containing capacitors concealed inside the light fitting which are not usually replaced. These are not to be confused with the igniter, which is replaced regularly for the maintenance of the light fitting and which, in some cases, also contains a small capacitor (Danish EPA, 2000 and 2015). The capacitor length is typically 5–15 cm, and it can be cylindrical or box-shaped. Capacitors typically contain 10–30 g of pure PCBs and typically weigh 100–300 g (Danish EPA, 2015).

Labelling Capacitors for Mains Voltage

Frequently, it will not be readily evident whether a capacitor contains PCBs. Normally, capacitors are labelled with the name of the manufacturer, type number, and year of production. The production year may be stated using two digits together with month or week of production. For example, the label ”7235” means that the capacitor was produced in week 35 in 1972 (Danish EPA, 2015) while ”42.67” means week 42 in 1967 (Techno Consult & Demex, 2005). If the capacitor dates from or before 1986, or cannot be dated, there is a good chance that it contains PCBs (Danish EPA, 2015).

There is no clear correlation between the product name of the capacitor and the presence of PCBs. If the make, type number, and year are stated, this can be compared with information from the mapping of PCBs in materials and indoor air (Grontmij & COWI, 2013). This resource is available via a link within the Danish EPA guidelines on handling PCB-containing capacitors in fluorescent light ballasts (Danish EPA, 2015). If one wishes to confirm whether a capacitor contains PCBs, it can be sent for chemical analysis at a testing laboratory (Danish EPA, 2015).

Mapping Capacitors in Fluorescent Light Ballasts

Light fittings potentially containing capacitors with PCBs are typically found in large office buildings, industrial and storage premises, institutions, hospitals, and other buildings. There may also be fluorescent light ballasts in basements, garages, kitchens, and rooms with similar uses in private dwellings. Please note that capacitors should be mapped, not only the light fittings.

In buildings with many light fittings, it is necessary to obtain information as to whether these have been wholly or partly replaced or whether extensions or conversions have been built. It is important to question, for example, whether light fittings could have been replaced in offices or accommodation spaces, but not necessarily in the basement. Each building should be considered an independent unit (see Section 4.1.2, Building Portfolio).

Replacement

Leakages in a PCB-containing capacitor may cause PCBs to emit to the surroundings and an actual leakage form capacitors with PCBs in fluorescent light ballasts can affect the indoor air significantly (see Section 1.6.1, Factors Affecting PCB Concentrations). It is extremely risky, therefore, to have this potential source in the building. The difficulty and expenses associated with removing PCBs from contaminated materials is reason enough to identify and remove these capacitors before they might contaminate the surroundings. If the visual inspection discloses fluorescent light ballasts potentially containing capacitors with PCBs, such capacitors should be removed or, conversely, one must make sure that they do not contain PCBs. If they contain PCBs, the Danish EPA (2015) recommends that either capacitors or light fittings be replaced. When replacing old fluorescent light fittings with new and more energy-effective ones, energy savings of 25–40 % can typically be achieved (Danish EPA, 2015). Likewise, the Danish EPA (2015) recommends that fluorescent light fittings from the period 1950–1986 are not kept, stored, or reused without determining whether the light fittings contain capacitors with PCBs.

5.2.5 Other Materials Containing PCBs

Depending on the building type and function, a variety of construction products have been used which potentially contain PCBs. The preliminary mapping in connection with the health-related assessment of the building should single out those construction products which are most likely to contain PCBs (see Table 17). As for waste characterisation, it will be necessary to identify all materials which potentially contain PCBs, to inspect potential sources, to assess what can be considered ”identical”, and to collect samples in selected locations.

The following materials may contain PCBs (see also Table 17 with descriptions substantiate the risk of PCB content in Danish construction products relative to building type).

Sealant Tape

Pre-compressed sealant tape of bituminous polyethylene was used during the period 1960–1976 in caulk around windows, in partition walls, and interior closure joints. PCBs were discovered in a few cases (Jensen et al., 2009; Grontmij & COWI, 2013).

Putty and Thermal Putty

Window putty may have been plasticised using PCBs to avoid it hardening with age and shrinking. Thermal putty was used for sealing (e.g., between the glass pane and the wood in a window). It adheres to glass, metal, and wood.

Adhesives

PCB-containing adhesives may have been used in floors, wainscot, ceilings, laminated structures, elements, and worktops.

Cables, Wiring, Switches, Plates

In Denmark, no PCBs have been discovered in cables, wiring, switches, and plates. However, in theory these could contain PCBs. These materials could also be tertiary contaminated sources.

Fillers

Fillers may contain PCBs. When collecting samples of e.g. paint on interior concrete walls, please remember that they are normally filled to conceal the holes otherwise visible in the surface.

Anti-Skid Surfacing

Anti-skid surfacing used on, among other places, industrial floors and access balconies may contain PCBs. They normally consist of thick paint or rubber with an admixture of quartz to prevent skidding. This makes cleaning difficult, and the surfacing tends only to be used where it is strictly necessary. Anti-skid surfacing may occur on ordinary balconies if the walkway surface is painted. PCB-containing anti-skid surfacing of the brand Acrydur was used in Denmark (Danish Business Authority & Danish EPA, 2010).

Lacquer

There are a few examples of floor varnish with admixed PCBs. Similarly, to paint, varnish can sorb PCBs from the air and thus become a tertiary contaminated source.

Linoleum, Vinyl, and Carpets

Linoleum is a flooring material of organic origin with a woven reinforcement. Flooring may be produced with added PCBs or fixed with PCB-containing adhesive. It can also be tertiary contaminated via the air (see Section 1.4.7, Flooring Compounds and Flooring).

Please note that in specific buildings, flooring may have been partially replaced while the rest is considerably older and may be subject to greater tertiary contamination.

Self-Levelling Flooring Compounds

Self-levelling flooring compounds containing PCBs were widely used in Norway. However, thus far in Denmark PCB-containing self-levelling flooring compound applications have only been confirmed in industrial and office buildings and only in a small number of multi-storey residential buildings.

In the national mapping of PCBs in materials and indoor air, 52 samples of flooring compound were collected and 56 % of the samples indicated a PCB concentration exceeding 0.1 mg/kg (Grontmij & COWI, 2013) (see 1.4.7, Flooring Compounds and Flooring).

Tile Adhesives

Tile adhesive is placed on the reverse side of a tile to fix it to a surface. PCBs may have been admixed to tile adhesives.

Waterproofing Materials, Waterproofing Membranes, and Rubber Surfacing

In wet rooms (or other locations with high water loads), PCB-containing waterproofing membranes, rubber surfacing, or rubber sheets may have been used.

Laminated Plastic

Laminated plastic with admixed PCBs may have been used for among other things worktops, cupboard doors, and perhaps panels installed in areas subject to less water load. These may also be tertiary contaminated.

Wax, Polish, and Similar Products

No PCBs have been confirmed in floor treatment materials such as wax and polish in Denmark, but this cannot be ruled out.

Plaster, Mortar, Concrete

In Denmark, no cases have yet been confirmed of admixed PCBs in plaster, mortar, and concrete. However, this cannot be ruled out. The materials may also be secondary and tertiary contaminated.

Building Boards

No PCBs have been confirmed in building boards in Denmark. However, in theory adhesives containing PCBs could have been used within building boards (i.e., plywood, chip board, and perhaps even gypsum boards).

5.2.6 Secondary Contaminated Building Materials

If PCBs have been confirmed in caulk, it is very likely that PCBs have migrated to adjacent materials and caused secondary contamination. There is not necessarily any correlation between PCB content in caulk and the PCB content in adjacent materials. PCB content in caulk may have changed over time, or the caulk may have been replaced, resulting in low concentrations of PCBs deriving from the original caulk. PCBs from secondary contaminated materials may have migrated back to the new caulk.

The depth of migration is likely to be relative to the porosity of the materials. PCBs generally migrate further into brick and aerated concrete than into concrete. PCBs from caulk also migrate into wood adjacent to it. However, the degree of penetration varies (see Section 1.5, Primary, Secondary, and Tertiary Sources, and Section 8.7, Secondary Contaminated Materials). PCBs can also migrate into paint that it is in direct contact with caulk or filler containing PCB, for example.

PCBs from sealant and mounting materials in insulating glazing units can migrate into adjacent window casing. If previous glazing units contained PCBs, the remaining window casing may have been contaminated (see Section 5.2.2, PCBs in Insulating Glazing Units).

Paint originally containing PCBs may have contaminated adjacent materials, such as concrete floors. If subsequently painted over with new paint, this too may contain PCBs.

PCB Renovation

If a building is renovated due to the presence of PCBs, mapping is required to ascertain the extent of the secondary contamination. This might derive from PCB-containing caulk around interior doors and windows and samples should therefore be collected at an increasing distance from the edge of the caulk. Here, it is recommended that investigators actually quantify the PCB content, as this will facilitate estimations of the extent of contamination in the building. It will then be possible to decide whether it would be appropriate to cut out the contaminated material or whether the secondary contamination should be extracted or encapsulated. In such cases, data on the degree and extent of contamination helps to determine how much of the material to treat. The waste must be characterised in accordance with the Statutory Order on Waste (see Section 3, Survey Prior to Renovation or Demolition).

Renovating Unrelated to PCB Issues

The need for mapping secondary contamination will depend on where PCB-containing building materials were discovered and what further action to take. Secondary contamination caused by exterior caulk replaced at an earlier renovation is unlikely to cause significant indoor climate problems. However attention should be paid to ventilation conditions and outside air supply. In a renovation scenario where a new climate envelope is built on the existing one, which formerly had PCB-containing caulk, it is essential to know the extent of the secondary source and whether it can be ignored or not. The waste must be characterised in accordance with the Statutory Order on Waste (see Section 3, Surveys Prior to Renovation or Demolition).

Demolition

When demolishing a building, it is necessary to determine how much material is contaminated and should be removed, in order for the remaining waste to be recoverable (see Section 3, Surveys Prior to Renovation or Demolition). Local authorities define the criteria for recoverable waste. In the City of Copenhagen (2014), the threshold for classification as PCB waste is 0.1 mg PCB/kg (corresponding to 0.02 mg sum7 PCB/kg). If the waste is below this limit, it is fit for recovery (see SBi Guidelines 242, Renovering af bygninger med PCB, 4 Affaldshåndtering (Renovating Buildings Containing PCBs, 4 Waste Management)) (Andersen, 2013b). Typically, PCBs will migrate to a max. depth of 5 cm in adjacent concrete (see Section 8.7, Secondary Contaminated Materials).

Samples should be collected from materials adjacent to interior and exterior PCB-containing caulk. If PCBs are confirmed in both exterior expansion joints and caulked joints, a sample from each type should be collected from a facade heavily exposed to the weather and from one which is less exposed.

In concrete buildings, samples should be collected indoors from load-bearing and non-load-bearing concrete walls, as these may differ in terms of composition and porosity and hence in levels of PCB concentration. Samples should be collected from adjacent materials near caulked joints as well as from expansion joints if both types contain PCBs. In addition, it is necessary to collect samples from concrete floors with expansion joints. If paint containing PCBs has been applied, the secondary contamination from the paint must be determined.

Insulating glazing units containing PCBs in the sealant or mounting materials may have contaminated the window casings. Putty and plastic sealant tape may be so effective in retaining glass panes that it may be necessary to smash the glass to extract it. In that case, it is necessary to assess whether it is worth separating the pane from the casing. If one decides to separate the casing, care should be taken to do so safely, and consideration should be given to what to do with the casing.

5.2.7 Tertiary Contaminated Materials

As with secondary contaminations, it is necessary to perform chemical analysis of samples to determine the extent to which PCBs occur in tertiary contaminations deposited on various surface areas. In demolition projects, waste separation is as essential as with secondary contamination. In renovation projects, analyses will determine whether it is necessary to remove or remediate these surfaces (e.g., by grinding down floors or removing wall paint).

Samples should be collected of each type of surface and each paint colour (see Section 5.2.3, PCBs in Paint). Likewise, samples should be collected from flooring materials (see Section 5.2.5, Other Materials Containing PCBs).

In the event of high levels of PCB concentrations in indoor air, furnishings will also be contaminated. This applies in particular to foam products (e.g., mattresses, sofas, and gymnastics mats).

5.3 Planning the Mapping

If there is reasonable suspicion that the building may contain PCBs, the building should be investigated further via mapping where air and/or material samples are collected. Section 5.1, Scope of Mapping details the extent of the mapping relative to background and point in time. The aim of the mapping may be to confirm or disprove the presence of PCBs or it may comprise more extensive surveys.

Preparations prior to the mapping process:

- A strategic plan for the actual mapping should be prepared (e.g., incorporating the historical building survey with data on the building and building components, drawings, use of materials, etc.).

- The mapping should be planned, including material sampling, categorized according to building materials (caulk, concrete, insulating glazing units, etc.) and their location inside and outside. Subdivisions of building components should be made (e.g., facades, floors, ceilings, roof, exterior and interior windows and doors, etc.).

- Drawings should be used to mark where material samples and/or air samples have been collected and photos should be taken of the test areas.

- It is recommended that more than one person be involved in executing the task.

- A list should be made of all necessary implements required for collecting samples beyond tools, air-measurement equipment and the PPE. Will ladders, lifts, scaffolding, or similar, be needed?

- Specific working environment issues should be interrogated, including the need to work around contaminations from asbestos and lead, for example.

- The mapping should be planned, including whether it will entail destructive sampling, or noise nuisance from pumps, and arrange the appropriate safety measures with the building owner or administrator (e.g., PPE, covering, screening, closing off, signage, and building occupancy during the survey).

- The accessibility of the sampling locations should be determined, both outside and inside.

- Occupants affected by the survey and sampling should be informed in good time prior to starting the work.

- Permission and access to premises and residences should be obtained before starting work.

If possible, one should ask the property administrator, operational staff, or another person who knows the building well, to participate in the mapping. Time should be budgeted to receive responses and test results within the mapping plan.