7. Determining PCB Content in Indoor Air

This section outlines the purpose of sampling, sampling method, measurement conditions, and practical sampling guidance. The number of measurements and their locations in a building are described in Section 2, Building Survey in Relation to the Indoor Climate.

No clear-cut method can be applied when collecting PCBs from indoor air. It is possible to vary several parameters and to select various measurement conditions. The different choices will depend on the purpose of the measurements and the practical circumstances.

7.1 Basis for Measuring PCBs in Indoor Air

This section describes the conditions affecting PCB concentrations in indoor air and the purpose of measuring them.

7.1.1 Variation in Concentrations

If PCB-containing building materials have been used, PCBs are highly likely to be present in the indoor air of the building. Concentrations of PCBs in indoor air can vary a great deal and are dependent on:

- Product type and PCB content of the product.

- Number of PCB-containing products used and their location in the structure, room, and building.

- Whole or partial replacement of the PCB-containing products during maintenance or previous renovation.

- Contamination of other building materials and surface areas with PCBs.

- Building usage and exposure (e.g., air exchange rate, temperature, weather impact, and occupant behaviour).

Knowledge of these issues should form part of the measurement planning.

Furthermore, measuring PCBs in indoor air depends on a series of measuring conditions where parameters such as sampling medium, flow rate, and exposure time can be varied.

Finally, measurements should be conducted under controlled conditions (e.g., air exchange rate, temperature, and building usage). The choice of measuring conditions depends on their purpose and the existing practical circumstances.

7.1.2 Purpose of Measurement

The aim of measuring PCBs in indoor air is usually to check:

- Concentrations relative to recommended action values.

- The effect of remediation interventions.

The best way to fulfil these two aims is to use slightly different methods when conducting the measurements.

If PCB concentrations are measured for the purpose of comparing them to action values, measurements should reflect the level of PCBs building occupants are exposed to. Measurement planning should therefore be based on measuring conditions for normal operational usage of the building. These types of measuring conditions are described in the guidelines from the Danish Transport, Construction, and Housing Authority (Danish Transport, Construction, and Housing Authority, 2015).

When PCB concentrations are measured for the purpose of documenting the effect of remediation interventions, pre- and post-remediation measurements should be taken during conditions which are as replicable as possible (to enable comparison). Hence, measurement conditions are extremely important and should include as little variation in air exchange and temperature as possible during a set period up to, and during, taking measurements (see Section 7.3, Measurement Conditions).

For large-scale renovations (with PCB remediation), it will probably be difficult to establish comparable sampling conditions from one sampling to the next. In this scenario, it can be very difficult to compare measurement results, not least due to the elevated concentrations occurring in connection with interventions (see SBi Guidelines 242, Renovering af bygninger med PCB, 2.2 Fysisk fjernelse (Renovating Buildings Containing PCBs, 2.2 Physical Removal)) (Andersen, 2013b).

Careful attention should be paid to the parameters affecting measurement results when they are to be interpreted. PCB concentrations in indoor air are highly dependent on temperature (see Section 1.6.3, Correlation Between Temperature and PCBs in Indoor Air).

7.2 Selecting a Method

This section describes the choice of sampling medium, flow rate, sampling period, and measurement reproducibility. Standardised measuring methods exist (see Section 1.7.1, Methodology), but in practice it can be difficult to completely adhere to a documented method. It is possible to deviate from the method if it can be documented that the deviations do not reduce the efficacy of the method. Moreover, two passive methods for determining PCBs in indoor air are described. Passive methods work without the use of active air suction.

This section highlights several conditions to be aware of when selecting a method.

7.2.1 Sampling Medium

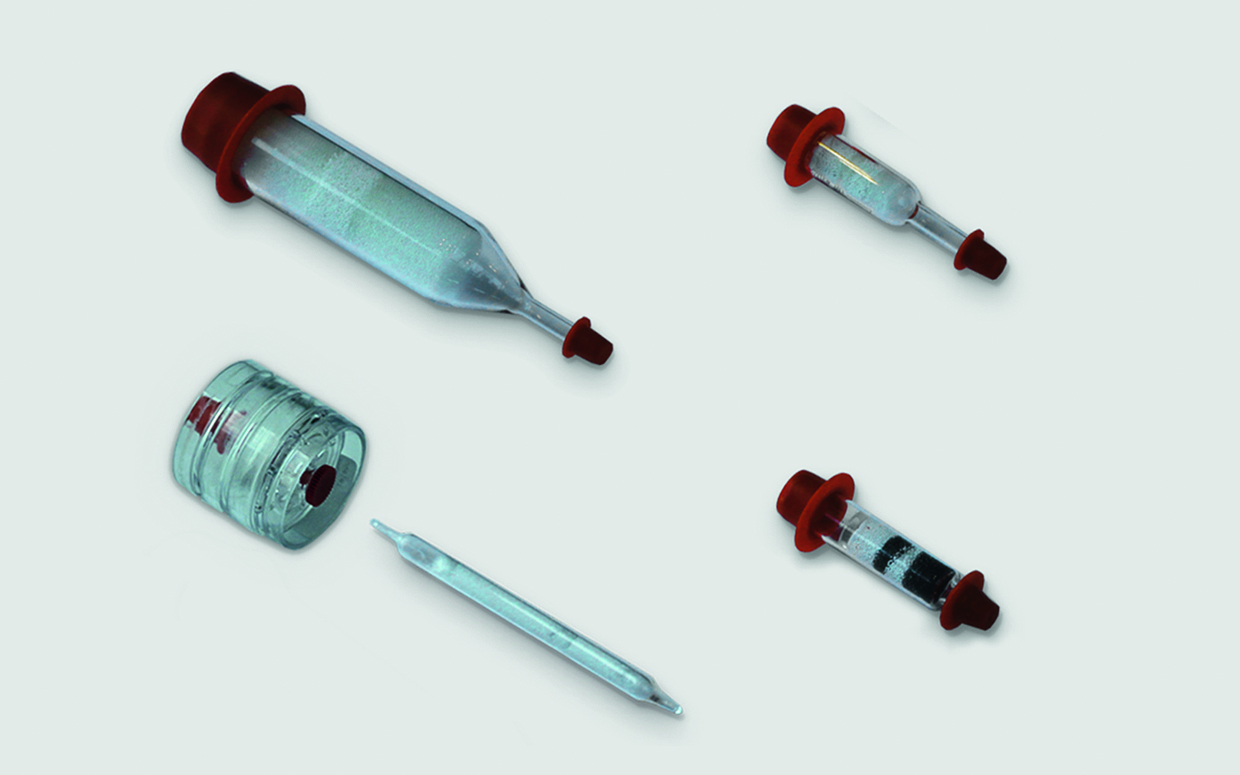

As described in Section 1.7, Air Measurements, PCBs are both gaseous and air-particle-bound and are effectively collected in a particle filter fitted with a sorbent, often a combination of polyurethane foam (PUF) and a resin (e.g., XAD-2). Glass is typically used as a container for the sampling medium. A fibreglass or quartz filter is used as a particle filter. The amount of resin and the size of the PUF will depend on the chosen flow and desired air volume. Figure 18 shows examples of sorbent tubes for collecting PCBs from the air available commercially. Some sorbent tubes contain a filter whereas others require the fitting of a pre-filter. The figure below shows a cassette with a pre-filter.

Figure 18. Different sorbent tubes used for collecting airborne PCBs available commercially. Some sorbent tubes have a pre-filter fitted prior to sampling. A cassette with a pre-filter is shown below the large sorbent tube.

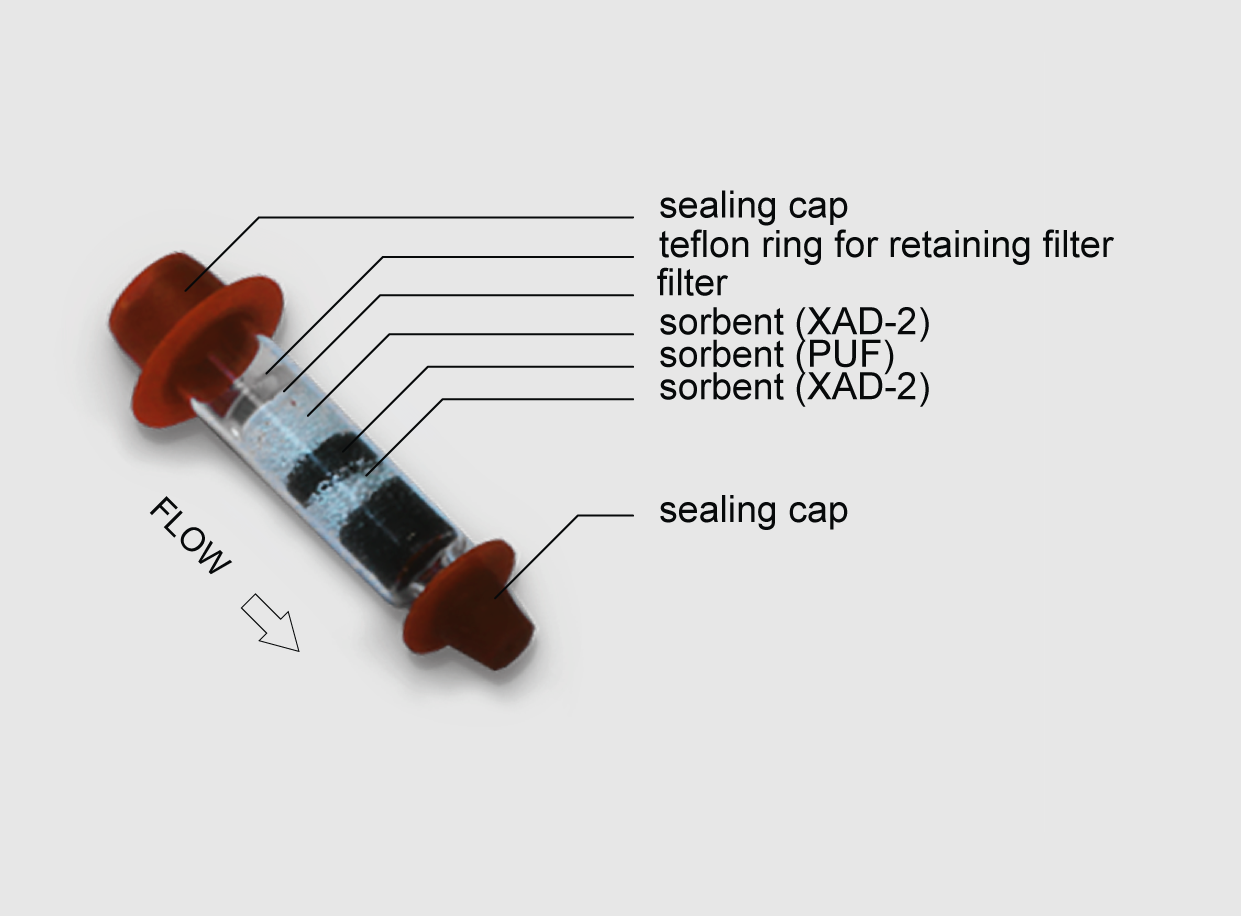

Figure 19 shows a commercially available sorbent tube which is 6 cm long and 1 cm in diameter at the inlet. The sorbent tube consists of a filter followed by a combination of XAD-2 and PUF sorbents. There are two XAD-2 zones with the latter functioning as a control zone. If the control zone is extracted separately, it is possible to check whether there has been a breakthrough in the sampling medium (XAD-2 and PUF) (see Section 7.2.3, Flow and Collection Period).

When selecting a sampling medium, it is important to ensure that the selected sorbent medium and method for subsequent extraction and clean-up are compatible (see Section 6, Chemical Analyses). Under certain circumstances, it might be advantageous to leave out PUF from the sorbent tube, as this makes the subsequent extraction and analysis slightly simpler (see Section 1.7, Air Measurements).

It is important to ensure that the selected flow rate is suitable given the efficiency of the sampling medium and that the breakthrough volume is not exceeded (see Section 7.2.3, Flow and Collection Period).

Figure 19. A commercially available sorbent tube with filter and sorbents (XAD-2 and PUF). The red sealing caps are removed, the thin end of the tube is connected to a pump, and air is pumped in through the large inlet of the glass tube.

Blank Samples

Both filters and PUF/XAD-2 are cleaned before use. Pre-cleaned collection tubes are available with a pre-fitted filter and sorbent. It is important to check that the tubes to be used are sufficiently clean so as not to compromise the measurements. Normally, one would take blank samples of the sampling media for each series of measurements. Given that analyses are costly, we recommend taking blank samples of each batch of collection media used.

Position of the Filter

In some commercially available glass sorbent tubes, the filter is placed at the front, packed against the adsorption medium, and held in place by a ring (see Figure 19). This kind of tube is easy to handle and potential problems with adsorption of PCBs to anything beyond the glass tube is avoided. An impactor can be fitted to the sampler, so that, during specific flow conditions, particles up to a certain size will be collected (PM2.5 or PM10) (US EPA,1999). If something that could change the inflow rate is placed in front of the sampler, or if a filter cassette with a separate filter, followed by a sorbent tube, is used, one should consider whether the materials or the transition piece could affect the measurement. For example, PCBs can be removed from the air by suction through PVC tubing (Lundsgaard et al., 2010).

7.2.2 Passive PCB Sampling

Two methods for passive PCB sampling have been developed (Vorkamp & Mayer, 2014) (see Section 1.7.2, Sampling Medium). These methods can be used to analyse the indoor air in rooms where excessive levels of PCBs are suspected. One method uses a petri dish whose bottom is lined with silicone (0.5 mm thick and 15 cm in diameter). The other method uses silicone-lined paper (40 cm × 60 cm) with a 1 µm thick layer of silicone. Material costs are low, and the samplers are simple and robust to operate. The data volume for evaluating the potential application of passive samplers is expected to increase with time (Danish Transport, Construction, and Housing Authority, 2015).

Over time, the sampling of PCBs from the air to silicone takes place in phases:

- A phase determined by kinetic conditions

- A phase operating with near-equilibrium conditions.

In the kinetic phase, airborne concentrations are determined based on the amount sampled with the passive sampler and an experimentally determined sorption velocity.

In the phase where near-equilibrium conditions are achieved between PCBs in the silicone and airborne PCBs, the amounts of PCBs in the silicone and information on the air-silicone partition coefficient is used to determine the air concentrations.

When utilising this measuring method, it should be made clear in advance whether the measuring method will be used in the kinetic phase or will be determined based on equilibrium conditions. Regarding the methods in question, the tests were characterised in the kinetic phase. This means that the sampled amounts of PCBs are adjusted by an experimentally determined factor to indicate the indoor-air PCB concentration. Based on a 24-hour exposure time, these methods proved to be highly sensitive and easy to replicate. The PCB concentration was overestimated 2–3 times when petri dishes were used whereas the PCB concentration was overestimated 3 times when using the silicone-lined paper (Vorkamp & Mayer, 2014).

Passive samplers can be utilised for the first step in a two-step investigation where they can indicate whether PCB concentrations in indoor air require intervention. If elevated concentrations occur, the next step requires measurements using an active method. This procedure can be used when a building owner requires that a major building portfolio be investigated (Danish Transport, Construction, and Housing Authority, 2015).

7.2.3 Flow and Sampling Period

As described in Section 1.7, Air Measurements, certain standards recommend high flow rates and relatively large air volumes while others recommend low flow rates. If concentrations of indicator PCBs are measured in indoor air in contaminated buildings, it is usually possible to achieve acceptable detection limits with low flow rates and relatively small air volumes (i.e., a short sampling time (in hours)). The advantage of low flow rates is that no large noisy pumps are required (Danish Transport, Construction, and Housing Authority, 2015).

With due consideration to the type and amount of the selected sampling medium (see Section 7.2.1, Sampling Medium), a flow rate of 1–5 l/min and an exposure time of between 4 and 24 hours should be applied. Furthermore, several issues should be given consideration when determining flow rate and exposure time, including detection limits, measuring concentrations in work rooms, dust collection, and source identification.

Limit of Detection

The limit of detection for measuring PCB concentrations should, under normal circumstances, not exceed 1 ng/m3 for individual PCB congeners. This is evident from the German standard VDI 2464 (Verein Deutscher Ingenieure, 2009; Danish Transport, Construction, and Housing Authority, 2015) (see Section 6, Chemical Analyses).

Work Rooms

According to the Danish WEA, measurements of PCB concentrations should be taken in work rooms during working hours and normal use (i.e., usually an 8-hour average concentration). Sampling over a 24-hour period can be misleading because ventilation outside working hours is often reduced compared to ventilation during working hours (Danish WEA, 2014). In this situation, noise from pumps should be considered given that occupants will continue to use the site.

Dust

Measurement of dust requires a specific inlet velocity and will therefore affect the choice of flow rate. The activity in the room dictates whether dust is whirled up and the inlet velocity dictates whether dust is collected (see Section 7.3.3, Normal Room Usage, Inlet Velocity, and Dust).

Source Identification

Under the same conditions, high-chlorinated PCB sources will emit fewer PCBs to the indoor air than low-chlorinated sources due to their lower vapour pressure. Special attention, therefore, should be paid to the measurement’s limit of detection if used to identify high-chlorinated PCB sources, as these will probably occur in low concentrations (see Section 1, PCBs – Properties and Applications).

7.2.4 Flow Rate Control

The flow rate should be subjected to further specified control and the sampling equipment tested for leakage prior to each measurement (Danish Transport, Construction, and Housing Authority, 2015, US EPA, 1999; Verein Deutscher Ingenieure, 2009). The flow should be as constant as possible during collection with a max. permitted variance of 10 %. By meticulous choice of equipment or via a pilot set-up, care should be taken to ensure that the pump can maintain a constant flow rate during the entire measuring period, especially if enough particulates are accumulated in the filter to alter the resistance, requiring a changed pump pressure to maintain a constant flow rate.

Flow rates can be determined in different ways, and it is possible, on a current basis, to regulate and/or register flow rates electronically or determine the air volume using a flow meter. If the air volume is determined behind the pump, a potential heating of the air should be accounted for. If the flow is measured near the head of the sampler, care should be taken that the flow meter does not affect the flow rate. If a pump with time-control is used and one is not present at the start and/or finish of the measurement, one must ensure that the pump effectively delivers the expected flow rate.

Breakthrough Volume

The sensitivity of the method is, for example, dependent on the amount of air collected. There is a limit to the volume of air drawn through the collection medium before material is lost from it. The air volume collected must be kept below the breakthrough volume where material is no longer retained by the collection medium. Once this threshold is reached, material is purged through the adsorption medium during collection and, at some point, breaks through it.

It is possible to use a method where the breakthrough volume has already been determined under specific measurement conditions. If measurement conditions are changed (e.g., when using a different sampling medium, a higher flow rate, or an extended collection period) one must ensure that the changes will not impair the measurement method. One can test a method and calculate the breakthrough volume or can use a sampling medium with an integral control zone. The sampling medium may thus be divided into two zones: a collection zone followed by a control zone (see Figure 19).

A separate analysis of the control zone can be used to assess whether a breakthrough has occurred in the collection zone. The zones can be separated by PUF or glass wool. If using a tube where the two zones are separated by PUF, the testing laboratory should be asked to analyse the PUF together with the collection zone, as a breakthrough in the collection zone will initially be trapped by the PUF.

Furthermore, care should be taken not to exceed the adsorption capacity.

7.2.5 Reproducibility

It is necessary to know the measuring uncertainty. This can be determined by conducting a series of parallel measurements to discover their mutual variance (see Section 7.3, Measurement Conditions). In the description of their methodology, the US EPA lists a measurement uncertainty of 5–30 % (US EPA, 1999). The analysis uncertainty alone can often be up to 30 %.

7.3 Measurement Conditions

When measuring indoor-air PCB concentrations, several issues should be considered. This section explains how to position the measurement equipment and describes issues which could affect the pre- and post-measurement of PCB concentrations in air.

7.3.1 Positioning of Equipment

The measuring height should be 1–1.5 m above floor level and the distance to walls should be a minimum of 1 m (Danish Standards, 2008a). The inlet of the sorbent tube should be horizontal or should point downwards (US EPA, 1999). This recommendation applies if sampling on a PUF medium, but if XAD-2 or another resin is used, it can be appropriate to turn the sorbent tube downwards so that the adsorption material is packed tightly. This minimises the risk of cavities forming, which let air through. If sampling dust, the measuring height should be 1.2 m and the inlet should point downwards (see Section 7.3.3, Normal Room Usage, Inlet Velocity, and Dust).

Furthermore, the position should avoid direct impact from injection air and any heat source.

7.3.2 Influencing Factors

The recommended action values stipulated by the Danish Health Authority are often used as a measure for annual mean values. Individual measurements can vary due to several changing conditions in the building and over time. To estimate variations, it is necessary first and foremost to know the reproducibility of the measurements (see Section 7.2.5, Reproducibility). Table 20 lists several conditions affecting the PCB concentration in indoor air. Occupant behaviour should be understood as follows:

- Are there occupants present?

- When and for how long are they present?

- What are the cleaning standards?

- How often are the rooms aired by occupants?

- Is mechanical ventilation used?

- Is the ventilation system based on air intake and exhausting?

- Is smoking allowed in the rooms?

- Is there a log burner or fireplace?

- Which activities are carried out in the rooms?

Operational building functions should also be considered, as there might be mechanical ventilation during working hours or (in the case of child-care institutions) altered heating and cleaning patterns during holiday periods.

Table 20. Conditions affecting PCB concentrations in indoor air.

Condition | Variations Inside the Building | Variation Over Time |

|---|---|---|

PCB source | Source location and strength | Temperature influence on source strength |

Climate/indoor climate | Ventilation conditions (incl. temperature and seasonal impact on air exchange rate) | Seasonal influence on source strength and ventilation |

Occupants | Occupant behaviour | Occupant behaviour |

Building | Operational function of building | Operational function of building |

Variations within the Building

The type, number, and location of PCB sources will be significant in terms of PCB content in the air in individual rooms in the building, just as temperature and air exchange rate are significant (see Section 1.6, PCBs in Indoor Air). It is important to be fully aware of these conditions to clarify the conditions underlying the measurements and to get an idea of the general operations of the building. One should assess whether air exchange rates should be measured.

Variation Over Time

Measurements made under comparable conditions indoors may have different outcomes because the difference between indoor and outdoor temperatures and incident solar radiation are subject to seasonal changes. This may influence wall temperature and thus the off-gassing of PCB sources. It may also alter the air exchange rate. The uncertainty associated with extrapolating from a single measurement to an annual mean value is estimated at 50 % for the lower recommended action value of 300 ng/m3 PCBs and 30 % for the higher recommended action value of 3,000 ng/m3 PCBs (Danish Transport, Construction, and Housing Authority, 2015) (see Section 9, Action Values and Temporary Abatement).

7.3.3 Normal Room Usage, Inlet Velocity, and Dust

Normal room usage means that occupant behaviour and activities are regarded as normal, and that temperature and ventilation are within the normal fluctuations for the room. This means no deep cleaning, no through draughts, and no partying for lengthy periods. However, it could mean that cooking and smoking, if relevant, continue as usual. It should be agreed to (prior to sampling) that log burners or fireplaces are not lit, nor should tumble driers with exhausts be used. Ventilation systems should be run as usual, including if there is air-conditioning.

EN ISO 16000-12 stipulates that measurements should be made during normal room usage (Danish Standards, 2008a). This is because many substances (including PCBs) are bound to particles whirled up due to occupant activities in the room and this affects airborne PCB concentrations. However, it is not always possible to measure when occupants are using the room normally and, in such circumstances, the amount of dust may be lower than typical, resulting in the underestimation of PCB concentrations (Danish Standards, 2008a).

According to Guidelines issued by the Danish WEA: Grænseværdier for stoffer og materialer – C.O.1 (Limit values for substances and materials – C.O.1), the inlet velocity should be 1.25 m/s when measuring dust (Danish WEA, 2011). For an average concentration, the measurement should be taken at a height of 1.2 m above floor level under representative conditions for at least 5–6 hours as the concentration may vary greatly within a short time (if there are activities in the room). Furthermore, the Danish WEA recommends measuring for approx. 1 hour during times with most activity. The sampling is performed using a membrane or fibreglass filter with a flow rate of approx. 2 l/min and an inlet velocity of 1.25 m/s, with the filter cassette opening pointing downwards (Working Environment Research Fund, 1997).

Since it will not always be appropriate nor possible to measure during usual occupancy of some rooms, these considerations should be part of the measuring strategy. If there are no occupants in the room to whirl up dust, it may be advisable to omit dust collection if achieving the desired inlet velocity requires manipulating inlet conditions, as this increases the complexity of the sampling.

Measurement Conditions and Recommended Action Values

The Danish Transport, Construction, and Housing Authority’s Vejledning for måling af PCB i indeluften 2014 (Guidelines for Measuring PCBs in Indoor Air 2014) (Danish Transport, Construction, and Housing Authority, 2015) recommends that dust be included in the measurement when assessing PCB concentrations relative to the Danish Health Authority’s recommended action values. The guidelines for measuring dust issued by the Danish WEA should therefore be complied with (The Working Environment Research Fund, 1997). This involves measuring for at least 5–6 hours and an air intake of approx. 2 l/min with an inlet velocity of 1.25 m/s and activities continuing in the room.

Fibreglass or quartz filters should be used instead of membrane filters (see Section 7.2.1, Sampling Medium). If the sorbent tube is fitted with an inlet to achieve the specified velocity, please note that certain materials and transition pieces between inlet and sorbent tube may influence the trapping of PCBs (see Section 7.2.1, Sampling Medium).

For pre- and post-remediation control measurement, it may be advisable to omit dust collection, as it will be difficult to replicate the same amount of dust and dust whirling activities over time.

7.3.4 Conditioning the Room Prior to Measuring

According to the standard EN ISO 16000-12 (Danish Standards, 2008a), as far as possible, conditions should be determined prior to starting measurements (see section 1.7.4, Measurement Conditions). The standard recommends ventilating the room well and then keep doors and windows shut for approx. eight hours or preferably overnight. Thereafter, measuring may begin. If rooms with heating, ventilation, and climate systems (HVAC) are surveyed, the system should be running as it would during normal operation for min. three hours prior to the commencement of sampling. Where set ventilation routines exist (e.g., in child-care facilities or schools), measurements should start when the room ventilation starts.

Measurement Conditions Relative to Recommended Action Values

If preliminary measurements are made to assess exposure levels of building occupants relative to the recommended action values, as far as possible, these should be made during normal building operations and occupant behaviour with doors and windows shut. The preceding airing may be omitted, but a conditioning of min. three hours before measuring is preferable.

Reproducible Measuring Conditions

For control measurements as part of systematic surveys, conditions should be as reproduceable as possible when repeating measurements. Measurement conditions should be those for normal building operations. There should be a brief airing out and conditioning prior to measuring with doors and windows shut for at least eight hours, or preferably overnight, with no occupant activities taking place during the measurement. For a major renovation project, however, normal operations may be difficult to achieve.

7.3.5 Temperature During Sampling Period

Temperature has a great influence on PCB-sources and hence PCB concentrations in indoor air. Measurements taken in winter will usually be lower than summer measurements made during otherwise comparable conditions. It is not possible to extrapolate from values measured during winter to summery conditions as the relationships between seasons, wall temperatures, and ventilation conditions are not sufficiently understood (Danish Standards, 2008a).

Temperature and any fluctuations during the same measurement period are significant to PCB concentrations (see Section 1.6.3, Correlation Between Temperature and PCBs in Indoor Air). The indoor-air temperature is therefore measured continuously throughout the measurement and conditioning period. At present, data is needed to ascertain whether relative humidity affects PCB concentrations in indoor air.

It is advisable that relative humidity measurements be taken to assess the overall indoor climate conditions.

Measurement Conditions and Recommended Action Values

If the aim of the measurement is to estimate PCB concentrations relative to the recommended action values, it is relevant to assess whether among other things the temperature could be considered average in relation to normal conditions.

Reproducible Measuring Conditions

If measurements are made to control the effect of remediation interventions, they should, as far as possible, be comparable over time (i.e., with as little temperature variation during measuring periods as possible and the same temperature and air exchange conditions for each measurement). This is a difficult task because weather conditions and seasonal changes will affect these parameters. If measurements are taken at night, outdoor temperatures will usually be more stable than in the daytime. Wind load on the building and hence the influence on air flow could also be reduced because wind velocity is often lower at night.

7.3.6 Measurement Protocol and Measuring Form

The form in Annex A can be used to specify ventilation conditions in the building. The forms in Annex B can be used when specifying measurement conditions.

7.4 Recommendations

This section summarises the recommendations of these Guidelines relative to measurement methodology and conditions.

7.4.1 Collection Method and Measurement Conditions

We recommend using the following:

- Particle filter of fibreglass or quartz followed by an XAD-2 and possibly PUF.

- A low flow rate (i.e., 1–5 l/min and 2 l/min) for dust collection with an inlet velocity of 1.25 m/s.

- A limit of detection of 1 ng/m3 for the individual indicator congeners.

Two procedures are recommended relative to measurement conditions: one for preliminary measurements and one for control of remediation interventions as shown in Table 21.

Table 21. Measurement conditions during preliminary control air measurements.

Preliminary Air Measurements Focusing on Exposure | Control Measurements Focusing on Replicable Conditions |

|---|---|

Occupants present | Occupants not present |

Normal operation | Normal operation |

Long collection period (between 4 and 24 hours) | Short collection period (min. 4 hours) |

Include dust collection1) | Omit dust collection |

Airing can be omitted | Airing prior to conditioning |

Min. 3 hours of conditioning | Min. 8 hours of conditioning |

Doors/windows shut during conditioning period and sampling | Doors/windows shut during conditioning period and sampling |

- Dust collection requires special conditions (see Section 7.3.3, Normal Room Usage, Inlet Velocity, and Dust).

7.5 Measurement Procedure

7.5.1 Preparation

Before visiting the measurement site, the following should be done in preparation:

- If the sampler comprises several components which need assembling (e.g., the filter in a filter cassette), this should be prepared in advance.

- The sorbent tubes should be packed sensibly (i.e., the material is packed tightly and evenly against the edge, preventing air from being drawn through cavities in the material. The filter should also lie straight and cover the whole suction area).

- Test tube batch numbers should be checked and blank samples should be taken for each batch used.

- Tubes from the same batch should be used for interrelated measurements.

Marking tape, or a similar alternative, should be brought to mark the area around the sampler. This should prevent occupants from disturbing it.

Prior to the visit, it is best to arrange with occupants that they do not light log burners or fireplaces, if applicable.

7.5.2 Step by Step Procedure

A room should be selected for sampling (see Section 2, Building Survey in Relation to the Indoor Climate). The exhaust tumble dryer should be checked and should not be running. Occupants should be asked not to used cooker hoods unless cooking. Depending on the purpose of the measurement, the room should be well-aired, doors and windows shut, and the room should be conditioned for min. 3 to 8 hours. The temperature data logger ID should be noted and the logger should be placed near the site where the air sample is collected. The temperature sensor should not be affected by exhaust air from the pump, nor should it be positioned in such a way that it is heated by incident solar radiation.

If there is any possibility of being exposed to the sampling medium, the person sampling should use gloves so as not to pollute the sample.

- The room should be checked for a suitable set-up position for the sampling train.

- Doors and windows should be shut.

- The mechanical ventilation system should be studied to determine whether the room is subject to intake or exhaust of air.

- If the temperature logger has not already been placed, the temperature data logger ID should be noted and the logger should be placed near the site where the air sample is collected.

- The sampler stand should be placed in the room min. 1 m from the walls and in such a way that prevents occupants from disturbing it. In necessary, the sampling area should be cordoned off.

- The sampler should be fitted into the stand at a height of 1-1.5 m, pointing horizontally or downwards. If dust collection is included, the stand should be placed at a height of 1.2 m and the inlet should be turned downwards and possibly fitted.

- The sampler should be connected to the tubing and pump and place the pump in such a way that it is slightly removed from the sampler.

- The pump should be positioned so that it will not fall due to vibrations and so that it is out of the way of occupants.

- The time should be noted and the pump started.

- The sampling train should be tested for leakage.

- The flow rate should be measured and noted. If it does not match expectations, check the sampling train again. If no fault is found here, adjust the pump to the desired flow rate.

- If the room is occupied, the sampling train should be marked with a note explaining what is going on, whom to contact, and instructions not to touch it or switch it off.

- The forms concerning ventilation and measurement conditions should be filled in (see Annexes A and B).

- The sampling train should be photographed, if relevant in such a way that the pump flow rate and timing are visible.

- A note should be left on the door about keeping doors and windows shut for the duration of the measurement period.

The outside temperature, barometric pressure, and assess wind impact (force and direction relative to the building) should be noted. Alternatively, data from the nearest measuring station can be used, available from the Danish Meteorological Institute’s (DMI) website (www.dmi.dk/dmi/index/danmark/vejrobservationer.htm) as well as weather forecasts for the nearest town or city (www.dmi.dk/dmi/index/ danmark/byvejr_danmark.htm). The expected interval for outdoor temperature, wind direction and force during the measurement period should be noted.

After the specified exposure time, the measurement is interrupted:

- The flow rate should be remeasured before stopping the measurement and the flow rate and time of stoppage should be noted (possibly stating the minute indicator on the pump).

- The sampling train should be photographed as done at the start.

- The plugs should be placed on the sampler after completed exposure. The sampled should be wrapped in foil and placed in a sealed plastic bag.

- The bag should be labelled with the place, date, air volume collected, identification of the person sampling, and a unique number indicating the measurement location.

- The room should be inspected and one should check that exit conditions are still met. Are the doors and windows still closed?

- Forms with should be filled in with information on weather conditions, etc. when dismantling.

The equipment should be taken away and the data extracted from data loggers on temperature and possibly air humidity. The temperature data should be checked during the measurement and conditioning period. The temperature variations during both periods should be assessed, including relative to each other (depending on the aims of the measurement). Are measurements made for the purpose of specifying exposure levels and does the process appear normal relative to the rate of occupancy? Were the measurements made with the highest level of reproducibility and how stable is the temperature? DMI’s website should be checked and the barometric pressure should be noted etc. The photos from sampling start and finish should be compared to check whether the sampling train was identical in both (i.e., to check that it was not disturbed during the measurement period). Using the photos, the pump records (if relevant) should be checked to ensure that they agree with the notes entered in the forms.

Air samples should be delivered to the testing laboratory. If the sample is stored for more than a few days, it should be placed in an airtight glass or metal container. Samples should not be stored at temperatures above 22 °C (e.g., in a warm car).

7.6 Passive Air Sampling Procedure

Two passive sampling methods are described in Vorkamp & Mayer (2014) and Vejledning for måling af PCB i indeklimaet 2014 (Guidelines for Measuring PCBs in Indoor Air 2014) (Danish Transport, Construction, and Housing Authority, 2015). For both passive sampling methods, the silicone used to trap PCBs must be cleaned before use. This is done to remove impurities that will interfere with the chemical analysis following the exposure. Acetone has proved very effective for cleaning the silicone (for more details, see Vorkamp & Mayer (2014)). A glass lid is placed on the petri dish containing silicone. After cleaning, the samplers are stored in aluminium bags sealed with tape.

A room is selected for the measurement. When the seal is broken or, in the case of the petri dish, when the glass lid is removed, the measurement starts as the silicone in the sampler is now being exposed to air. When handling the passive samplers, gloves are worn so as not to pollute the sampler.

The open petri dish with the silicone is typically placed on a table or on top of a cupboard in the room where the measurement is made. The petri dish is exposed for 24 hours after which the glass lid is replaced, and the sampler is returned to its aluminium bag and sealed with tape. The bag is then labelled with clear and unambiguous identification.

The silicone-lined paper is unfolded and hung with metal clamps (e.g., on a line or a clothes dryer in the selected room). The paper lined with silicone is exposed for one week after which it is refolded and returned to the aluminium bag and sealed with tape. The bag is then labelled with clear and unambiguous identification.

The aluminium bag with the exposed sampler is then sent to the laboratory for analysis for the seven indicator PCBs. Conversion to air concentrations is based on a specific sorption rate (Vorkamp & Mayer, 2014) (see Section 7.2.2, Passive PCB Sampling). The sorption rate is dependent on temperature. Measuring the temperature during the measurement period is therefore recommended. The temperature is managed in essentially the same way as for active sampling (Danish Transport, Construction, and Housing Authority, 2015) (see Section 7.5, Measurement Procedure).