8. Determining PCB Content in Building Materials

This section explains how to collect samples from different building materials with the aim of determining PCB content. First, a few general considerations concerning sampling will be listed.

Section 2, Building Survey in Relation to the Indoor Climate, describes where and how many samples to take.

8.1 Considerations When Sampling

Since building materials may potentially contain PCBs, the following should be observed when sampling:

- Avoid dispersing the PCBs

- Avoid exposure of the person performing the sampling (or others) to PCBs

- Avoiding cross-contaminating the samples

- Label the samples clearly and unambiguously

- Consult the testing laboratory

Avoid Dispersing the PCBs

PCBs may diffuse through plastic. To avoid dispersing PCBs, it is necessary to wrap samples in aluminium foil, which is impermeable to PCBs. Furthermore, wrapping the sample in aluminium foil will protect it against light.

Thereafter, the sample can be placed in a labelled plastic bag. If the sample is stored for several days, it should be stored in a glass or metal container, as any off-gassed PCBs will not migrate through glass and metal.

Avoid Exposure of the Person Performing the Sampling (or Others) to PCBs

When sampling potentially PCB-containing materials, note that PCBs are harmful to health and may be absorbed through the skin. The person sampling should therefore wear suitable PCB-resistant gloves and should avoid direct dermal contact. The At-intern instruks IN-9-3, PCB i bygninger (Internal WEA Brief IN-9-3, Building-Related PCBs) (Danish WEA, 2014) outlines how to protect oneself when sampling. If there a risk of the sampling procedure generating dust or heat, further measures are required such as respiratory protection, protective suits, and other PPE (Danish WEA, 2014).

Avoid Cross-Contaminating the Samples

Sampling should be conducted to avoid cross-contamination (i.e., transferring material from one sample to another). Tools used to collect material samples should therefore be cleaned after each sample collection to avoid residual PCBs on the sampling equipment from coming into contact with a sample without PCBs (even small amounts will register in the analysis, which will then be misinterpreted). Tools should be used where knife blades or test tubes are replaced after each sampling procedure. If samples are collected where PCB content is expected to gradually vary, sampling should be performed from low to high concentrations. This applies among other things to a secondary contaminated concrete samples where the sampling is started furthest away from the primary source.

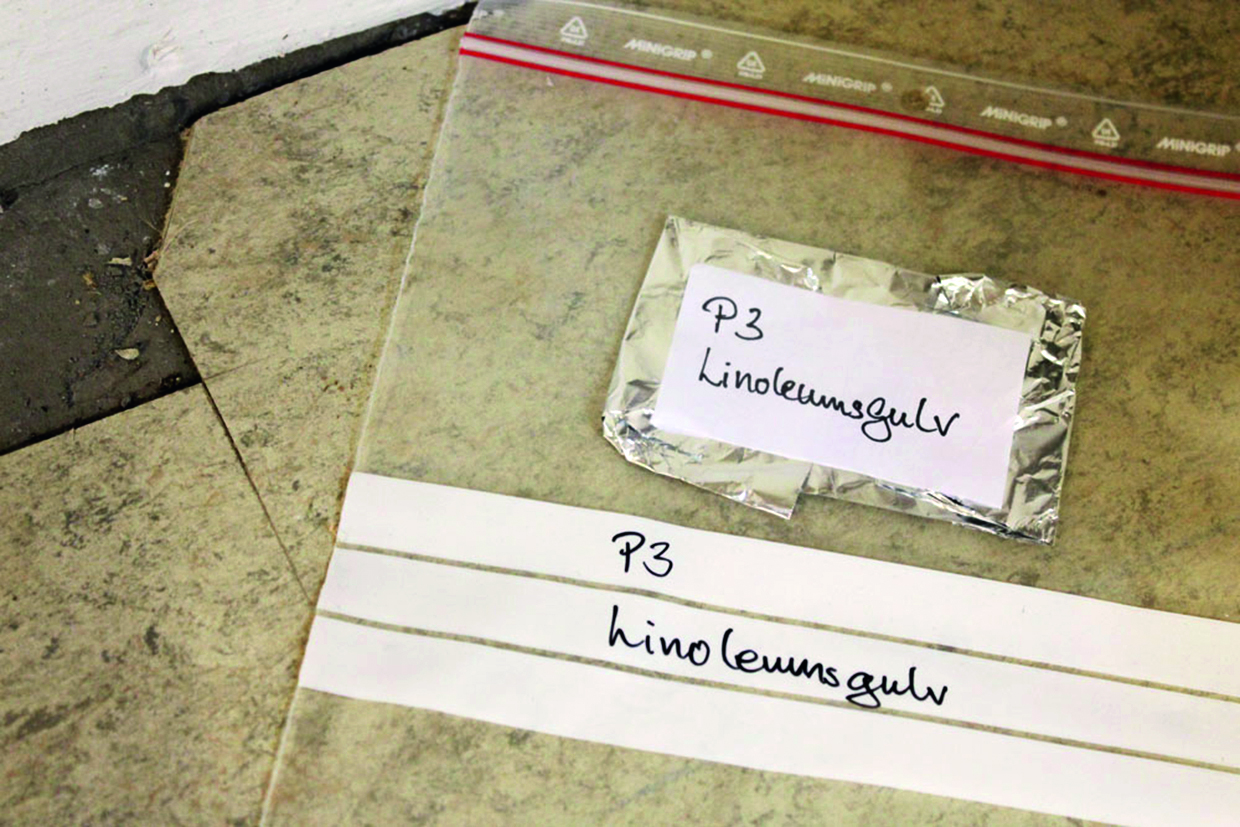

Label the Samples Clearly and Unambiguously

Tracing the sample back to the place of collection is essential. This requires careful documentation as to where each sample was collected and name them with a logic and appropriate labelling system. The location or name of the building should be stated and one should ask the testing laboratory to disclose this information in their test report. It is advisable to include sample type, date, place, name of the person sampling, and sample number. This is noted in a logbook where other information about the sample and sample location is entered.

Storage

In theory, the samples should be analysed as quickly as possible after collection. Dry samples, including caulk, should be stored in a dark place at ambient temperature and should be shipped quickly to the analysis laboratory (Danish Standards, 2008b). The samples should never be left in a warm car. If the samples are stored for more than two days, the plastic bag containing the sample must be put into an airtight glass or metal container with a disc of aluminium foil between lid and container, since not all lid packings are vapour-impermeable.

Consult with the Analysis Laboratory

It is advisable to establish positive dialogue with the analysis laboratory, both to ensure the correct treatment of the samples and to obtaining the data they require. Sufficient sample material should be collected given the analysis detection limit (i.e., how small an amount of the substance can be detected) (see Section 6.3, Limit of Detection).

8.2 Caulk

PCBs were used in certain caulking compounds (see Section 1.4.4, Caulking Compound). Section 8.2.2, Tools and Other Equipment discusses choice of tools while Section 8.2.3, Step-by-Step Procedure: Collecting Caulk Samples, discusses procedures for sampling caulk.

8.2.1 Caulk Type and Trade Names

During the period 1950–1976, PCBs were used as plasticisers in certain caulking compounds. PCBs were primarily used for polysulphide plastic caulk where PCB content was as high as 30 %. During this period, caulking compounds of this type were sold under the trade names of Thiokol, Thioflex, Vulkseal, Vulkfil, Lastomeric, 1K, Terostat, PRC, and Rubberseal (see Section 1.4.2, Usage and Residual Amounts of PCBs).

8.2.2 Tools and Other Equipment

The caulking compound can be cut out with a hobby knife or hollow metal piping (Ø 7–10 mm) can be used to punch it out. If the caulk is very hard a chisel can be used. Table 22 describes tools, application areas, and PPE that can be used when sampling caulk. Given that concentrations in the surface may be lower than in the deeper layers of the caulk, samples must be collected of the entire depth of the caulking compound. The analysis laboratory should be consulted to determine how much sampling material is required. Experience shows that a min. of 3 cm, but preferably 5 cm is required. If metal piping is used, the same piece is used to collect several samples to obtain sufficient sampling material.

Other tools without interchangeable parts (e.g., knife blades) must be cleaned between samplings, wiping them with paper soaked in acetone (www.sanerapcb.nu). Note that special rules apply in working environment legislation for working with hazardous materials, including acetone (Danish WEA, 2003).

Table 22. Tools, applications, and personal protective equipment (PPE).

Tool | Advantages and Disadvantages | PPE and Protection |

|---|---|---|

Hobby knife  | Advantages:

Disadvantages:

|

|

Test tube with handle  | Advantages:

Disadvantages:

|

|

Knife  | Advantages:

Disadvantages:

|

|

Chisel  | Advantages:

Disadvantages:

|

|

Figure 20 shows the tools and equipment that may be used for caulk sampling. They include aluminium foil, kitchen paper, disposable gloves, plastic bags, pincer pliers, test tube with handle, caulking compound to re-set the joint, chisel, hobby knife, knife, measuring tape, screwdriver, and acetone.

Figure 20. Tools and equipment used for caulk sampling.

8.2.3 Step-by-Step Procedure: Collecting Caulk Samples

Step by step procedure:

- Put on clean disposable gloves.

- Cut approx. 5 cm along both sides of the caulk and make sure to get all the caulk out or take 3–5 cut-outs with a metal test tube. If applicable, free caulk from backer rod attached, insulation, or any residual contact face.

- Wrap the sample in a piece of aluminium foil and put it in a closed/sealed plastic bag. For composite samples (see Section 5.2.1, PCBs in Caulk) the size of the samples should be as uniform as possible. Place the samples on the same piece of aluminium foil and wrap them together. If using a metal test tube and if the sample remains inside the tube, wrap the tube in foil and place it in a sealed plastic bag.

- Clean the sampling equipment carefully by wiping it with kitchen paper soaked in acetone. If using a knife, discard the used blades. Dispose of acetone-soaked kitchen paper in an airtight container.

- Remove disposable gloves and place them in a waste bag for PCB-contaminated waste.

- Label the sampling bag and follow the selected labelling system.

- Mark the sampling location on a sketch with the sample designation and any comments on the appearance of the sample (e.g., if it contains paint). Take a photo of the sampling location and the caulked joint, if relevant.

- Measure length, width, and depth of the caulk if you need to calculate the building’s PCB content.

- Fill the cavity where the sample was taken with new caulking compound or seal the cavity with solid tape.

- Wash your hands after sampling.

- Send the labelled samples to the testing laboratory, remembering to add the name of the location/building.

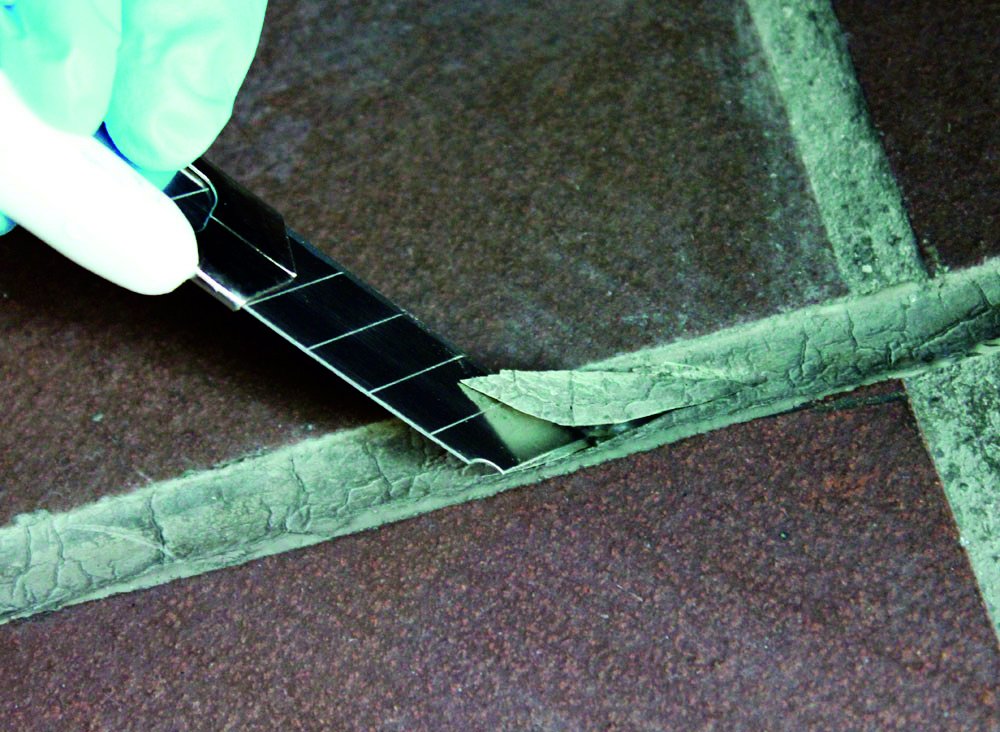

Figure 21 illustrates caulk sampling using a test tube. Figures 22 and 23 show caulk sampling using a knife, whereas Figure 24 shows sampling of an expansion joint between concrete floor decks using a knife.

Figure 21. Caulk sampling. The picture on the right shows a composite sample collected with a test tube across a large area (e.g., a facade joint).

Figure 22. Caulk sampling using a knife.

Figure 23. Caulk sampling using a knife.

Figure 24. Sampling an expansion joint between concrete decks. Photo: Danish Technological Institute.

8.3 Insulating Glazing Units

The following sections describe glazing units possibly containing sealants with PCBs, which type of tools to use to collect sealant samples, and how to collect and handle the samples.

8.3.1 PCBs in Insulating Glazing Units

In Denmark, PCBs were used in sealants and mounting materials for glazing units until the ban in 1977, and certain foreign glazing units used PCBs until 1980 (Vestforbrænding et al., 2008; www.ruteretur.no). Approx. 75 % of manufacturers used sealants containing PCBs during the period 1967–1973 (see Section 1.4.5, Insulating Glazing Units). There is a stainless-steel or aluminium spacer profile between the two layers of glass in the unit, secured to the glass with butylene (primary sealant). Underneath this spacer profile is the sealant that potentially contains PCBs.

Figure 25 illustrates the location of the various parts. The sealant tape may be replaced with putty. Glazing units were manufactured with the spacer profile soldered in place (www.sanerapcb.nu). These glazing units do not usually contain sealant with PCBs but may have sealant tape or putty containing PCBs. The caulked joint around the window is shown on the Figure and this, too, may contain PCBs.

Figure 25. Cross section of insulating glazing unit with window casing in a wall. The edge sealant, sealant tape, primary sealant, top sealant, and the wall joints are marked in orange (see Annex C, Caulked Joints). The orange markings indicate the spots where materials with admixed PCBs may have been used. Putty rather than sealant tape may have been used.

It is not readily discernible whether the edge sealant of a glazing unit or the mounting materials used contain PCBs. More recent glazing units have product information stamped on the spacer profile. Some older glazing units contain this information, but not all do. For example, an insulating glazing unit produced in October 1972 can be marked ”10/72”. If the glazing unit is marked, it is possible to determine whether it was made before or after 1977. If the unit is not labelled, it is likely to predate 1977 and could thus contain PCBs (see Section 5.2.2, PCBs in Insulating Glazing Units).

An insulating glazing unit of approx. 1 m2 could typically contain 50 g PCBs in the edge sealant (see Section 1.4.5, Insulating Glazing Units) and should normally be characterised as hazardous waste.

8.3.2 Tools and Other Equipment

To reach the edge sealant, it is necessary to either remove the glazing unit from the casing or to break up some of the casing. Alternatively, the pane can be smashed to remove the edging profiles and mounting materials. Tools are needed to loosen the pane or break up the casing. To remove the pane, a suction cup may be required. Furthermore, a knife is needed to cut out a section of the sealant. The edge of the pane may be covered in putty or a top sealant containing PCBs. If the edge sealant contains PCBs, please note that PCBs may have migrated to window casing and the air space between the panes. The precautionary measures issued by the Danish WEA must be observed (Danish WEA, 2014). The pane may break during the collection of samples in the edge sealant and PPE such as gloves and protective glasses must be worn.

Figure 26 illustrates some of the tools and equipment required for the collection of samples from the insulating glazing unit edge sealant. These include aluminium foil, kitchen paper, disposable gloves, plastic bags, a knife, a sheath knife, a screwdriver, and acetone. Please note that special working environment rules apply when working with hazardous substances and materials, including acetone (Danish WEA, 2003).

Figure 26. Tools and equipment used for collecting samples of edge sealant in insulating glazing units.

8.3.3 Step-by-Step Procedure: Collecting Samples from Sealant in Glazing Units

When sampling from windows with profiles retaining the glazing unit in the window casing:

- Put on suitable gloves and other PPE, see section 8.3.2, Tools and Other Equipment.

- Place suction cups with handles on the glass pane.

- Remove the bead profiles from the casing.

- Gently loosen the glazing unit from the casing to reveal the edge sealant and leaving room for cutting. Alternatively, tilt the pane and collect the sample from the top. Remember to manoeuvre the glazing in the casing with spacer blocks.

- Cut a piece from the edge sealant using a clean, sharp knife or chisel. 'Peel' off a length of approx. 10 cm, corresponding to at least 2 g of the sealant along the pane. There will usually be an accumulation of sealant in the corners (www.ruteretur.no).

- Place the sample on a clean piece of aluminium foil and wrap it up. Place it in a sealed plastic bag.

- Carefully clean the sampling equipment by wiping it with kitchen paper soaked in acetone. If a knife is used, discard the used blade. Place the acetone-soaked kitchen paper in an airtight container.

- Remove gloves. Depending on the make of gloves, it might be possible to use them again.

- Label the plastic bag with the sample according to the selected labelling system.

- Mark the sampling location on a sketch with the sample designation. Take a photo of the sampling location, if relevant. Note the information on the spacer profile in the glazing unit, or lack of same if no information is provided.

- Reassemble the pane and window casing. Place the glazing unit into the casing as this will protect against potential migration of PCBs. Remember to manoeuvre the glazing in the casing with spacer blocks.

- Wash your hands after sampling.

- Send the labelled samples to the testing laboratory. Remember to state the name of the location/building on the label.

Figure 27 illustrates an insulating glazing unit ready to be tilted outwards. Figure 28 illustrates the edge sealant inside the glazing unit.

Figure 27. Insulating glazing unit ready to be tilted outwards. Photo: Danish Technological Institute

Figure 28. Edge sealant in a glazing unit. Photo: Danish Technological Institute.

Insulating glazing units mounted in putty or with sealant tape in wooden casings can only be cut out using a special wood-cutting device. If the putty or plastic sealant tape is hard, it will often be necessary to smash the pane to get to the edge sealant.

8.4 Paint

The following sections describe the types of paint potentially containing PCBs, which tools to use to collect paint samples, and how samples are collected and handled.

8.4.1 PCBs in Paint

Paint may have been admixed with PCBs. They may also have been contaminated by airborne PCBs or via contact with PCB-containing building materials, mixing equipment, pigment, or plastic additives (fibres). In buildings with PCB-contaminated indoor air, there will usually be more than 0.1 mg/kg total PCBs in the paint, which is the limit set by the City of Copenhagen (2014) for determining whether to class waste as uncontaminated and hence recoverable. It is not possible to determine whether paint contains PCBs from its appearance and it is necessary to collect samples and have a chemical analysis done.

PCB-containing paint was often used in contexts requiring resilience to abrasion and weather. In Germany, PCB-containing paint was used as a fire-retardant in ceiling panels, and emergency exits (see Section 1.4.6, Paint).

The thickness of the paint is important when collecting samples. Often, the paint will consist of several layers, of which one or more layers may contain PCBs. All layers must be included in the sampling. Wallpaper could also be included. The underlying substrate should be avoided if possible, as it will affect the weight of the sample and thus provide misleading data on the amounts of PCBs in the paint.

8.4.2 Tools

Paint samples can be collected using a sharp knife, spatula, a triangular or hard-metal tipped scraper tool. Please remember to wear PPE.

Figure 29 illustrates the tools and equipment that may be used when collecting paint samples. They include aluminium foil, kitchen paper, disposable gloves, plastic bags, a knife, a paint scrapers, and acetone. Please note that special working environment rules apply when working with hazardous substances and materials, including acetone (Danish WEA, 2003).

Figure 29. Tools and equipment used for collecting paint samples.

8.4.3 Step-by-Step: Collecting Paint Samples

Assess whether other types of PPE than gloves are necessary.

- Put on disposable gloves.

- Mark a delimited area of 5–10 cm × 10 cm on the painted surface and scrape the paint, keeping to this area if possible. All paint layers should be scraped off at the same time, avoiding scraping the substrate. A min. of 1 g and preferably 2 g of paint should be collected. If necessary, remove the paint in flakes or by cutting off a piece of wallpaper.

- If collecting the sample from a vertical wall, a bag for collecting the scraped-off paint can be taped to the wall. Also, a piece of aluminium foil can be placed on the floor, fitted closely to the wall. If a scrape is taken from the floor, the scraped-off paint is collected with a spatula, or a similar tool. This can be cleaned after use.

- Wrap the scrapings in a clean piece of aluminium foil and place them in a sealed plastic bag.

- Clean the sampling equipment carefully by wiping them with kitchen paper soaked in acetone. Place the acetone-soaked kitchen paper in an airtight container.

- Remove disposable gloves and leave them in the waste bag.

- Label the plastic bag containing the sample according to the selected labelling system.

- Mark the sampling location on a sketch with the sample designation. Take a photo of the sampling location, if relevant.

- Wash your hands after sampling.

- Send the labelled samples to the testing laboratory and note the name of the location/building on the label.

Figure 30 illustrates scrapings and collection when sampling paint.

Figure 30. Scraping off a paint sample. Photo: Danish Technological Institute.

8.5 Flooring

PCBs may be present in plastic-based flooring. The product Acrydur was used during the period 1955–1975 in catering kitchens, industry, printing firms, utility rooms, basements, and access balconies. This product did contain PCBs during this period (Danish Transport, Construction, and Housing Authority and the Danish EPA, 2010).

New flooring might have been laid above the old flooring, in which case samples must be collected from both layers.

Collect a sample with a suitable knife like the one used for sampling caulk. Protective gloves must be used. Cut out a piece measuring approx. 10 × 10 cm from the flooring. It may be necessary to loosen the flooring from the substrate using a screwdriver, or a similar tool. Wrap the sample in aluminium foil and place it in a sealed, labelled plastic bag (see Section 8.2.3, Step-by-Step Procedure: Collecting Caulk Samples). Figure 31 illustrates an example of sample collection from a linoleum floor. Arrange with the testing laboratory whether the whole floor sample should be analysed or only the surface (i.e., not any fibres and adhesive on the back).

Figure 31. Collecting samples from linoleum flooring. Photo: Danish Technological Institute.

8.6 Floor-Levelling Compound

In other Scandinavian countries, PCBs were identified in floor-levelling compounds. Collect the samples as described in Section 8.7.3, Step-by-Step: Collecting Concrete Samples.

8.7 Secondary Contaminated Materials

The following section describes materials potentially contaminated by PCBs, the tools used for sampling, and how to collect and handle samples. It also describes, how samples can be collected from an exposed surface area. The surface area can be exposed after cutting out secondary contaminated materials or clean-up (e.g., of paint).

8.7.1 PCBs in Adjacent Materials

PCBs from caulk or other PCB-containing materials can migrate into adjacent building materials (see Section 1.5.2, Secondary Contamination of Building Materials). A qualitative assessment of whether PCBs have migrated into adjacent materials could be the first aim of the sampling. For renovations, the PCB content in the building materials should be ascertained and thus which kinds of sources they are and/or how to manage their disposal. If the building is designated for demolition, its PCB content should be mapped to facilitate a safe working environment and waste management.

PCBs in concentrations exceeding 50 mg/kg (i.e., hazardous waste), can typically migrate 0.5–5 cm into the adjacent concrete along exterior caulked joints (Andersen et al., 2013).

Studies from the flats on the Farum Midtpunkt housing estate indicate considerable variation in the migration depth into adjacent materials which is dependent (e.g., on the porosity of the adjacent materials) (Haven & Langeland, 2011). PCB-concentrations exceeded 50 mg/kg almost 3 cm into the adjacent concrete, 1 cm into the adjacent woodwork, and 7 cm into the adjacent Masonite along caulked joints. The study from the PCB-mapping of materials and indoor air indicated that PCBs migrate deeper into coniferous wood that into aerated concrete and brick (Grontmij & COWI, 2013). As such, no clear and unambiguous results exist for the extent of migration into wood (see Section 1.5.2, Secondary Contamination of Building Materials).

8.7.2 Tools and Other Equipment

Samples of concrete, brick and/or aerated concrete can be cut, milled, knocked, or drilled out as core samples. When sampling materials, precautionary measures in relation to dust and heating must be observed (Danish WEA, 2014). The sample should be large enough to be representative of the sampling location, but small enough to facilitate posting and crushing. Arrangements should be made with the laboratory regarding the sample amount required.

If the adjacent material is brick, it is easier to knock out a whole brick rather than drilling out a sample.

The choice of tools depends on the purpose of collecting the sample. If the aim is to ascertain whether migration of PCBs has occurred, it will be sufficient to knock off a piece of material with a hammer and chisel. If, on the other hand, quantitative

information regarding migration depth is required, drilling, milling, or sawing will usually be necessary. The following will address sampling for the purpose of attaining a quantitative characteristic of the migration depth.

In concrete, PCB concentrations across concrete at right angles to the caulk will often follow an exponential curve and the graph can be determined by measuring concentrations at varying distances from the caulk. Close to the caulk, PCB concentrations will often be high and not necessarily form part of the typical graph curve, as there may be caulk residues left from the caulked joint. This is particularly common on brick samples (Andersen et al., 2013).

Core samples can be drilled from concrete, or holes can be drilled, and the dust collected. In some cases, a corner can be cut from a concrete slab and then cut up. The method will depend on the specific circumstances and how samples can be collected.

There is a risk that heating generated by the drilling can affect the sample, but the extent of this problem remains undocumented. To keep the temperature down, drilling can be done in several short bursts. Samples collected as drill dust are likely to be highly affected by temperature and should, as far as possible, be avoided.

Concrete Cores

If concrete core samples are collected, the core diameter should be sufficiently large in relation to the material adjacent to the caulked joint and the distances from it whose PCB content one wants to determine. Furthermore, the impact occurring on the surface of the core during drilling should be considered when selecting a diameter. When drilling, the concrete is heated, and drill dust is generated which may be drawn up along the core. A diameter of 3 cm is suitable to characterise the PCB content per cm. Agree with the analysis laboratory how the drill core will be treated on the surface, how it will be cut up and how to crush the slices. Concrete aggregate is included in the crushing. The laboratory should be informed about how the core was collected and whether the drilling was done towards the caulk (the source of contamination) or away from it. If the latter is the case, the testing laboratory can clean up the core surface to avoid the potential contamination.

If concrete samples are collected (e.g., from concrete walls near expansion joints) a large core can initially be drilled from the wall transverse to the joint. Carefully mark the location of the joint on the core. Then drill a core from the main core corresponding to a profile from the joint into the concrete (see Figure 32). Alternatively, this sample could be chiselled out to avoid heating.

Several smaller cores could be cut out at increasing distances from the joint and then cut up corresponding to their location from the joint (see Figure 33).

If collecting a sample near a door, window casing, or an end wall, it is a good idea to drill through the wall. To minimise the migration of dust, one should drill from positions of low concentrations towards higher concentrations, if possible (i.e., start furthest away from the joint and then drill towards the joint) (see Figure 34).

Figure 32. Taking out a large core and a small core transverse to the large core relative to the location of the joint.

Figure 33. Small cores are cut out at increasing distances from the joint. Afterwards, the cores are cut into slices corresponding to their location from the caulked joint.

Figure 34. The isometric cut shows a core drilled from a wall adjacent to a door frame or window casing.

When investigating the migration of PCBs from the caulk around a window or door to the frame or casing, a core sample should be drilled from the location where the PCB contamination is expected to be lowest towards where it is highest, if possible.

If the caulk is removed, a core sample can be drilled directly from the adjacent material at a right angle to the caulked joint. Before drilling, clean the surface carefully for caulk residue and avoid drawing caulk residue along the surface of the core sample.

Figure 35. Collecting drill dust for analysis of PCB concentration in a specific building component. Holes are drilled next to one another or at an angle depending on how close to each other they need to be. The figure on the right illustrates the collection of drill dust.

Drill Holes

If nothing else is possible, the migration of PCBs from caulk between two concrete slabs can be determined by drilling holes in the wall and collecting the drill dust at an increasing distance from the caulked joint. This method has several disadvantages. The drill dust could be heated to an extent that would affect the PCB content and this may produce misleading results due to PCB off-gassing from the dust. The sample will also represent only a minute part of the concrete. The porosity of the concrete is presumed to influence the degree of PCB migration and a single pebble can influence the porosity of the small sampling area. If this method is selected, due consideration should be given to the depth of the joint relative to the wall’s surface. If the joint is recessed 1 cm relative to the wall's surface, the first cm of the drill hole should not be part of the sample. Depending on how close the samples need to be, holes can be drilled next to each other or staggered at an angle (see Figure 35).

8.7.3 Step-by-Step Procedure: Collecting Concrete Samples

- Put on clean disposable gloves and other protective equipment.

- Find a location with no risk of accidentally drilling into electrical installations in the wall.

- Drill or saw out the sample. If possible, start where concentrations are expected to be lowest (i.e., furthest away from the joint). Cut or drill in several stages to minimise heating.

- Mark the sample indicating which end is closer to the contaminated source. In the case of drill dust, samples are numbered according to a chosen marking system.

- Wrap the sample in a piece of aluminium foil and place it in a sealed plastic bag.

- Clean the sampling equipment carefully by wiping with kitchen paper soaked in acetone. Place the acetone-soaked kitchen paper in an airtight container.

- Remove disposable gloves and leave them in the waste bag.

- Label the plastic bag containing the sample with the selected labelling system.

- Mark the sampling location on a sketch with the sample designation and comments on the appearance of the sample (e.g., if it contains paint). Take a photo of the sampling location and the caulked joint, if relevant.

- Measure the length of the caulked joint if you need to calculate the building’s PCB content.

- Wash your hands after sampling.

- Send the labelled samples to the testing laboratory and remember to mark it with the name of the location/building.

Please note that special working environment rules apply for work with hazardous substances and materials, including acetone (Danish WEA, 2003). If it has not been possible to drill in a direction from low to high concentrations, the laboratory should be informed. Ask them to clean the surface of the core sample before cutting it up to determine PCB concentrations at varying distances from the caulked joint.

8.7.4 Sampling Behind a Painted Surface

PCBs from paint can migrate into the underlying surface of brick or concrete. However, based on experience, this migration is often not as pronounced as that from caulk (Alslev et al., 2013b). The paint can be removed in an area of 10 × 10 cm and a sample collected from the first cm of the adjacent material. A subsequent chemical analysis will determine whether further sampling is required.

8.7.5 Sampling from an Exposed Surface

When cutting out secondary contaminated material (see an example of cutting out concrete round a door joint in Section 3.5.5, Calculating the Amount of Waste Containing PCBs)) or after clean-up (e.g., of a painted surface), it may be necessary to characterise the residual material. After cleaning up the surface (see SBi Guidelines 242, Renovering af bygninger med PCB, 3.3.2 Spredning af PCB til omgivende miljø (Renovating Buildings Containing PCBs, 3.3.2 PCBs Migrating to the Surrounding Environment) (Andersen, 2013b), approx. 1 mm of the surface can be scraped off with a hand tool and collected according to the same principles that apply to paint (see Section 8.4, Paint). Collecting sample deeper than 1 mm should be avoided, as this will influence the sample’s weight and thus give misleading information on the amounts of PCBs in the surface (as the surface layer may thus be diluted). It will often be difficult to scrape deeper than 1 mm on concrete using a hand tool, but in the case of brick, care should be taken not to scrape excessive underlying material into the sample.

8.8 Tertiary Contaminated Materials

Samples of tertiary contaminated surface areas such as paint, walls, and flooring were discussed above because these sample types could also be primary sources.

It may be necessary to collect samples from other materials (e.g., dust from a ventilation system or samples from furnishings including furniture, or curtains). PCBs are especially likely to have migrated to insulation or sealing materials of polyurethane foam or upholstery foam, and gymnastics mats, as well as various flooring types. Samples should be collected while wearing gloves. Make sure that your tools are clean and that they are cleaned again after collection. Wrap the sample in aluminium foil and a labelled plastic bag (see Section 8.1, Considerations When Sampling). Please note that if tertiary contaminated furnishings are moved into a room, one is moving a contamination source into a room.

In the case of a ventilation system, a composite sample can be collected consisting of aliquots of dust collected with a clean spatula from various places in the system. Collect 5 g of samples in total and inform the laboratory about the type of sample you have submitted. Prior to sampling, one should clarify with the laboratory how much sampling material they require and how to handle the sample.